A Wind Turbine of a New Type

Written by Fulmina Institut

The use of the new screw developed by the author in the construction allowed to create a wind propulsion system, which allows three to four times increase the efficiency of the collection of wind power, and this in different forms. And the combination in modular design allows to build wind dams with any given capacity. Thus a construction of the wind turbine was created that depending on the given tasks can be of different type: from a pocket version to wind dams.

The construction of the wind turbine is based on a number of "know-how" which allows to patent the development in leading countries of the world. The preliminary patent search was already carried out, which confirms the patentability of the product.

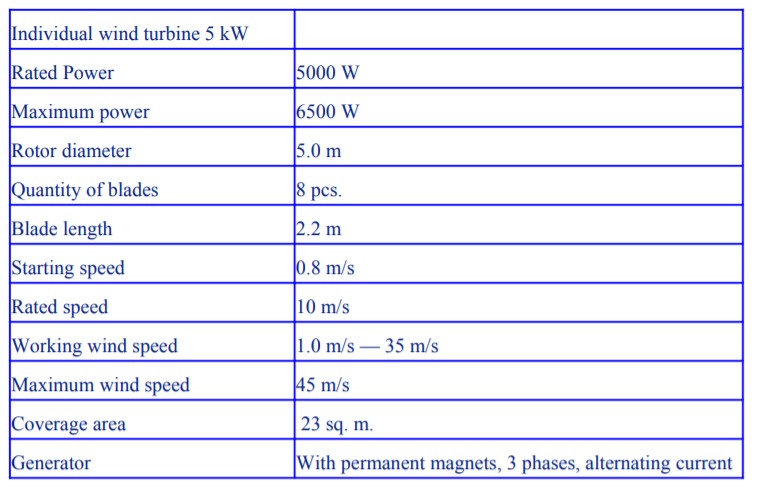

Individual wind turbine 5 kW

- The cost of one power unit of the wind turbine was reduced 2-3 times compared to the analogues due to increased efficiency.

- The basis of the wind turbine is the slow-speed ring oscillator. Its principle of operation - three-phase synchronous generator with contactless excitation from rare-earth magnets.

- The blade of the special design is made of glass-carbon or composite by a special technology and has a high resource.

- The applied eight-blade wind rotor scheme with a similar energy-conversion efficiency has several technical advantages:

- Higher operating torque of the wind rotor and this means less weight and lower price of the electric generator on 30-50%;

- The blade is attached to the shaft of the generator at an angle, that is the blade itself does not perceive the wind pressure on the bend, this is cheaper and more reliable.

Main version of the individual base wind turbine 5 kW

- Blades – 8 pcs

- Generator

- Wind Orientation System

- Wind propulsion system

- Mast mounting unit

- Assembly Kit

- Unit of power processing and battery charging

- Inverter – 5-10 kW

- Batteries – 4 or 8 pcs., for the operation of electrical appliances with a total capacity of 5000 watts for 20/50 hours

- Mast – 12-24 m

Specification of the Wind turbine 5 kW

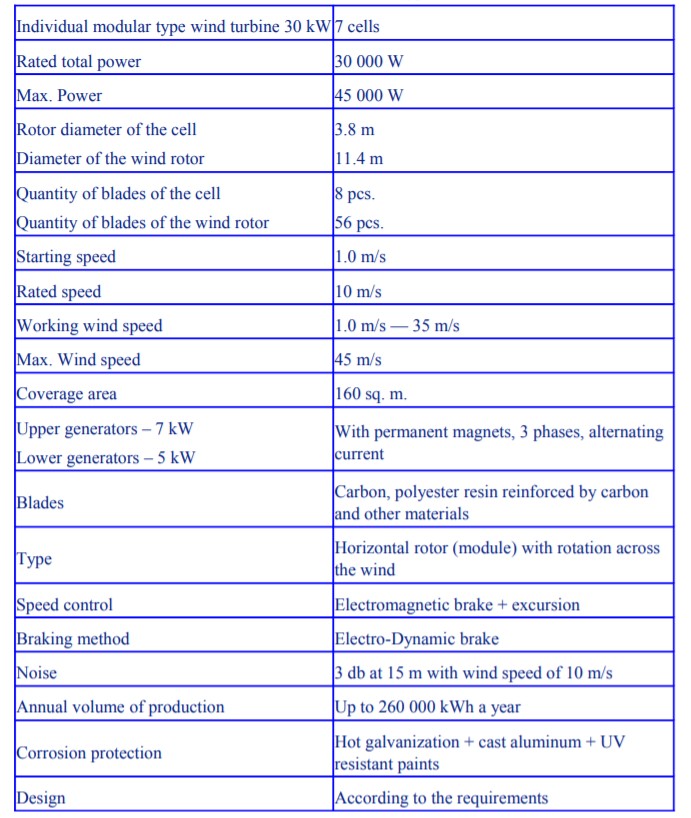

"Individual" modular type wind turbine 30 kW

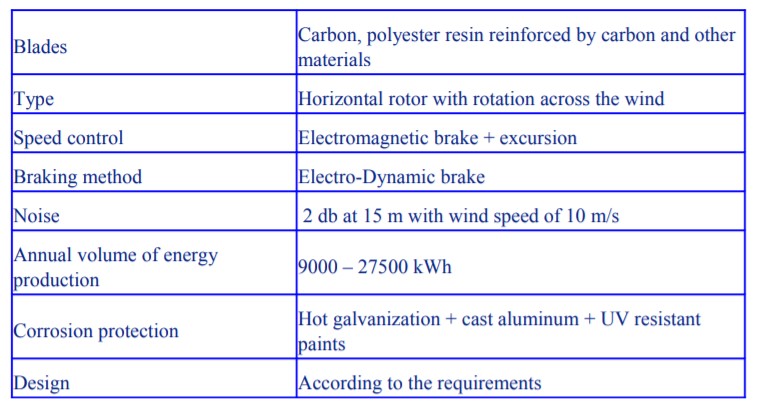

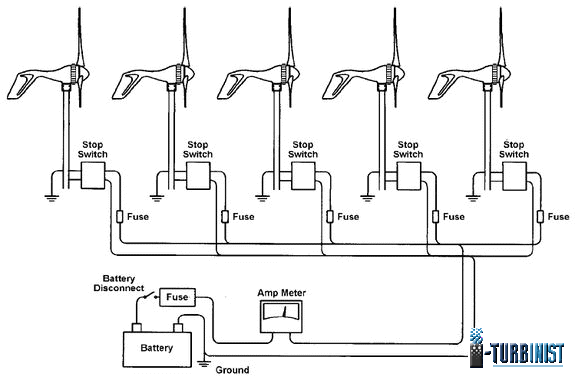

Each wind generator can function either individually or connected to the wind mill group to increase the performance. The modular cells of the wind mill not only give a more flexible design, but also do not spoil the looks reminding on a three-dimensional crystalline openwork structure. Thanks to this method of fastening of wind generators, it becomes possible to distribute the load on the whole system reducing the number of mounting bases and stretching the construction.

Since the blades occupy about 80% of the swept area, wind energy is used with an efficiency level of about 90%. Another advantage of the design on the base of conical helix is the elimination of vibration and reverse flow, which allows to minimize the danger to birds.

There is a difference in pressure in front and behind the rotor blades of the wind mill, this leads to higher performance. Even when the wind blows at an angle of 60 degrees into the rotor, it will start to rotate. No expensive software is required: The wind funnel directs itself automatically to the optimal wind direction based on the principle of a wind vane. The wind turbine is almost silent.

The productivity of 1 Wind turbine is annual electricity collection of 260,000 kWh/year.

Modular and monolithic structures are made of folded shells of convex or concave form on the basis of unification of elementary shells. As the basis for unification were taken the fragments of the surface of the torus with positive and negative Gaussian curvature. Thanks to two signs of curvature from elementary shells can be arranged constructions of various form, the geometrical accuracy of the surface of which is provided by various thickness of seams between shells. Prefabricated elements are connected with support rings and among themselves by welding of mortgage parts (reinforcing editions) and grouting of seams.

Technical characteristics of the modular type Wind turbine 30 kW

The wind turbine of a new type will reduce the cost of wind energy by 2 – 3 times. The increase in the size of the wind rotors will increase their efficiency at another 1.5 - 2 times, which would reduce the cost of 1 kWh of wind energy by 3 – 6 times.

The presence of an effective wind propulsion system allows to produce wind turbines of different power and design.

When installing a modular wind mill at an altitude of 40-60 m (commercial wind) in any region of the world with weak or medium winds, the cost of producing of 1 kWh of electricity will be by 2-3 times lower than the cost of obtaining energy by any diesel generator.

Developed wind turbine models: "Individual"

- Wind turbine ("Mini"), for personal consumption (from respiration, etc.), up to 0.1 kW;

- Wind turbine ("Small"), up to 1 kW, rotor working area (hereinafter – area) up to 1 sq. m.;

- Wind turbine ("Housing Wind Turbines"), up to 3 kW, area up to 7 sq. m.;

- Wind turbines ("Cottage"), 5 kw, area from 12 sq. m. (small farms, individual houses with increased consumption, etc.);

- Wind turbine ("Special"), up to 50 kW, area up to 130 sq. m. (farms, stations, boiler-houses);

"Individual" of modular type

- Wind turbine ("Child"), up to 1 kW;

- Wind turbine ("Auto 1"), up to 3 kW, uses blades (hereinafter - B) of 0.7 m, total area of seven individual Wind turbines in module (further area) up to 7 sq. m.;

- Wind turbine ("Carlson 1"), up to 10 kW, B up to 1.4 m, area up to 50 sq. m.;

- Wind turbine ("Carlson 3"), up to 40 kW, B up to 2.2 m, area up to 140 sq. m.;

"Wind park"

Each wind generator can function either individually or connected to the wind mill group to increase the performance. The modular cells of the wind mill not only give a more flexible design, but also do not spoil the looks reminding on a three-dimensional crystalline openwork structure. Thanks to this method of fastening of wind generators, it becomes possible to distribute the load on the whole system reducing the number of mounting bases and stretching the construction to create a wind dam.

- Wind turbine ("Front"), up to 500 kW, consists of 5 – 10 wind turbines of different power and size, its mast is in the form of a standard support of a high-voltage transmission line with height of 35 m.

- Wind turbine ("Fir"), up to 500 kW, consists of 5 – 10 wind turbines of different power and size, its mast is in the form of a standard support with height of 45 m.

- Wind ("Park 1"), from 2 to 50 MW, consists of 5 – 100 wind turbines of different power and size, its mast is in form of a standard support (tower) with height of 60 m.

"Wind dam"

The wind dam is installed individually in places with a constant wind flow in one direction, consists of a series of "Individual" Wind turbines of modular type, connected among themselves in a single construction, having a common connection (electric, mechanical, hydraulic).

The Wind dam, from 10 to 500 MW, consists of 10 – 100 modules of different power and size, its masts are in the form of standard supports, connected in a single structure up to 60 m high.

A Wind dam has its own special characteristics:

- Minimal windage due to the effective transformation of the wind flow (pressure) into the energy of rotation

- Density of stacking 0.9, including the module and the whole Wind park;

- High efficiency, or high wind utilization level;

- Uses the system of distributed coupling;

- As base for the Wind park are used modules that have 7 – 9 equal wind turbines installed by the hexagonal scheme (honeycomb) in volumetric execution of the bearing structure;

- Stationarity, orientation to the constant wind or side.

The statistics on energy generation systems in the world convince that wind power has already withdrawn from the category of "alternative", becoming one of the main areas for generation of the principal energy.

Copyright Fulmina Foundation

Powered by Froala Editor