A Fundamentally New Air Screw

Par Fulmina Institut

by Fulmina Institut

As result of a large volume of research works carried out in the 1990s, the author of this technology created holographic devices and installations of non-destructive interferometric control and measurements. These units allowed to study the forms of oscillations of turbine blades propulsion and attracted interest in the studying of existing and the creation of new propulsion devices for means of spatial movement.

Research conducted by the author for eighteen years led to the development and creation of a fundamentally new design of the propeller blade and the air screw itself. Patents on inventions have been obtained. The developed screw design allows up to four times increased traction compared to analogues. By creating a cumulative effect by the new screw, it is possible to increase the flow rate generated by this screw up to and beyond the one of the sound. This screw is intended for use on manned and unmanned vehicles in air, water and near the ground areas, as well as blower in fan and compressor systems.

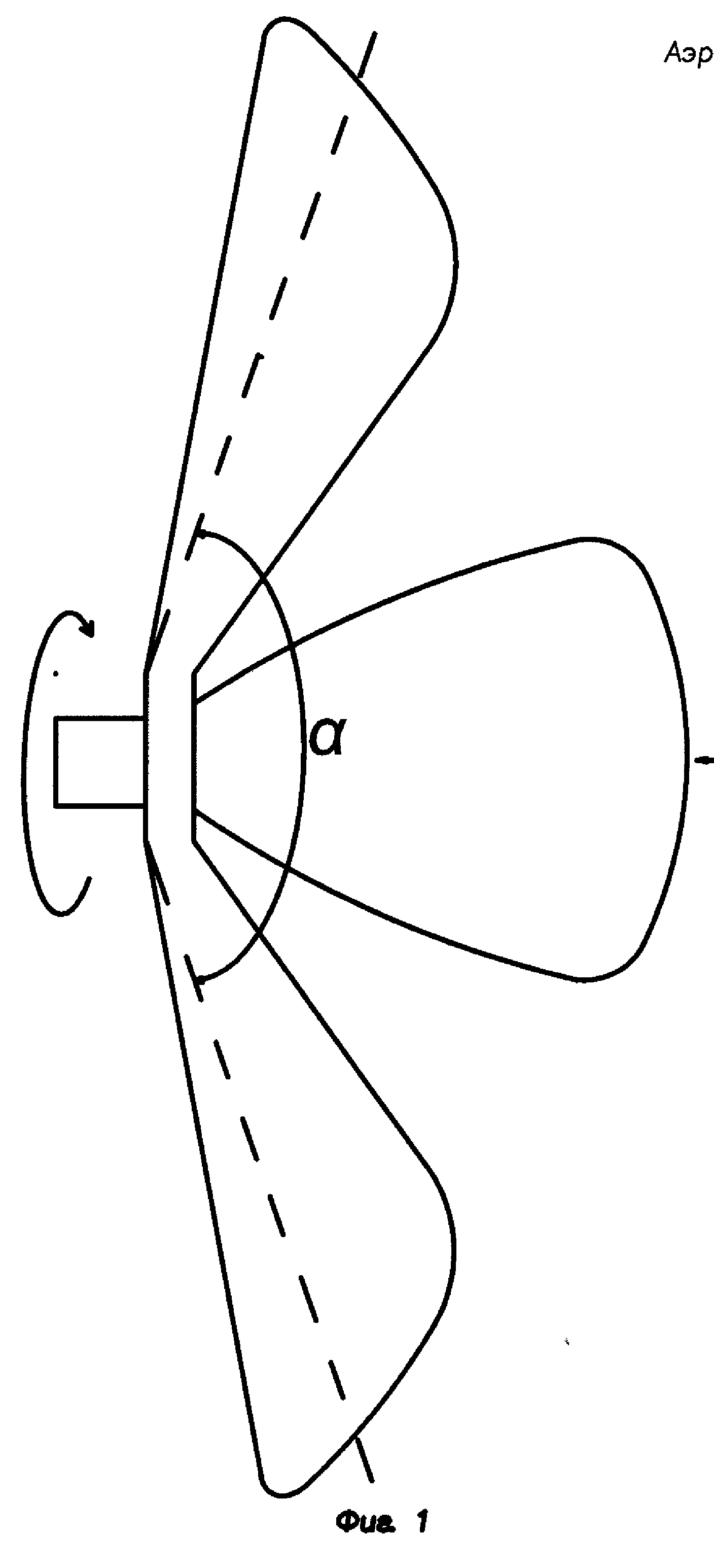

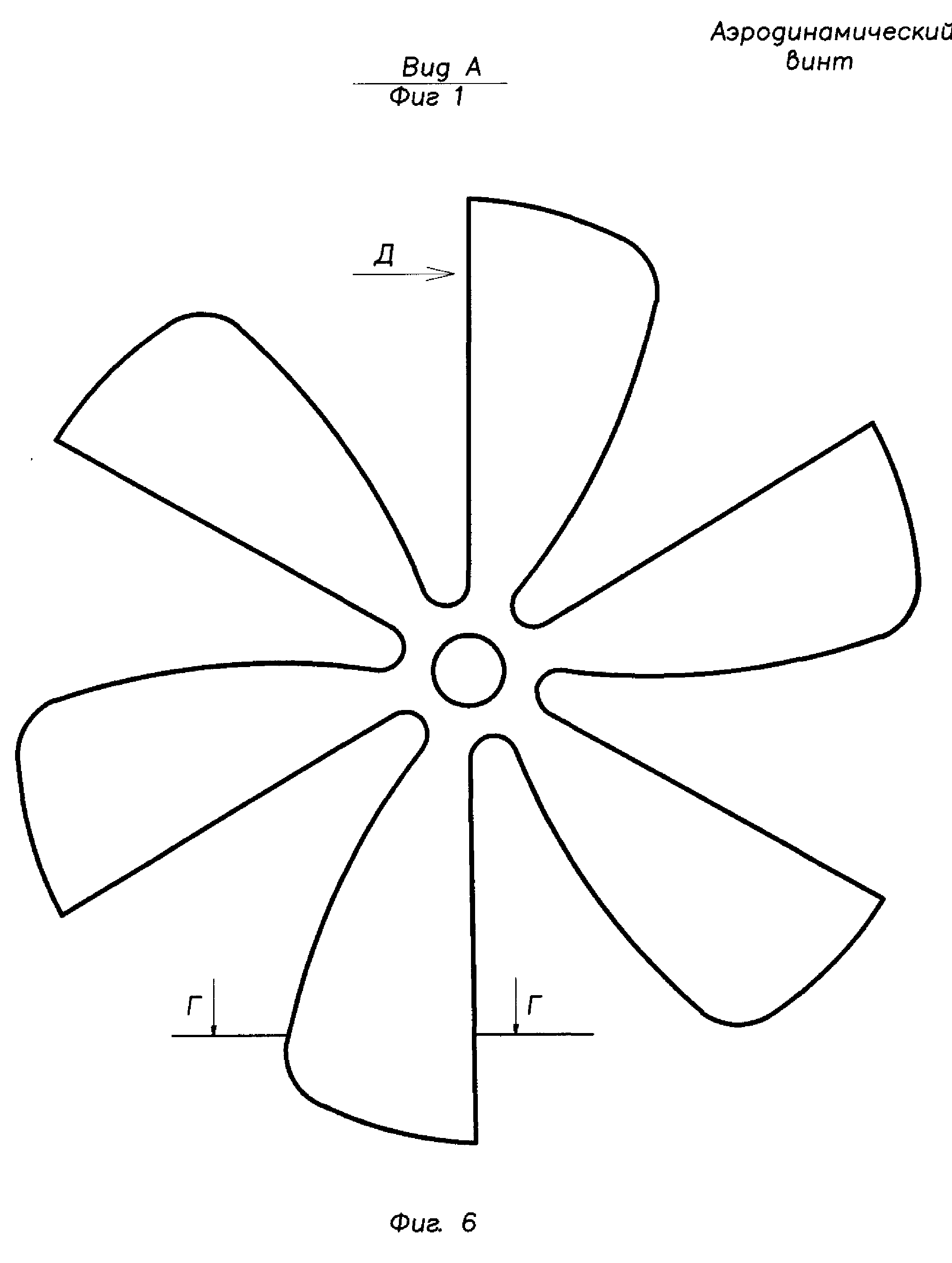

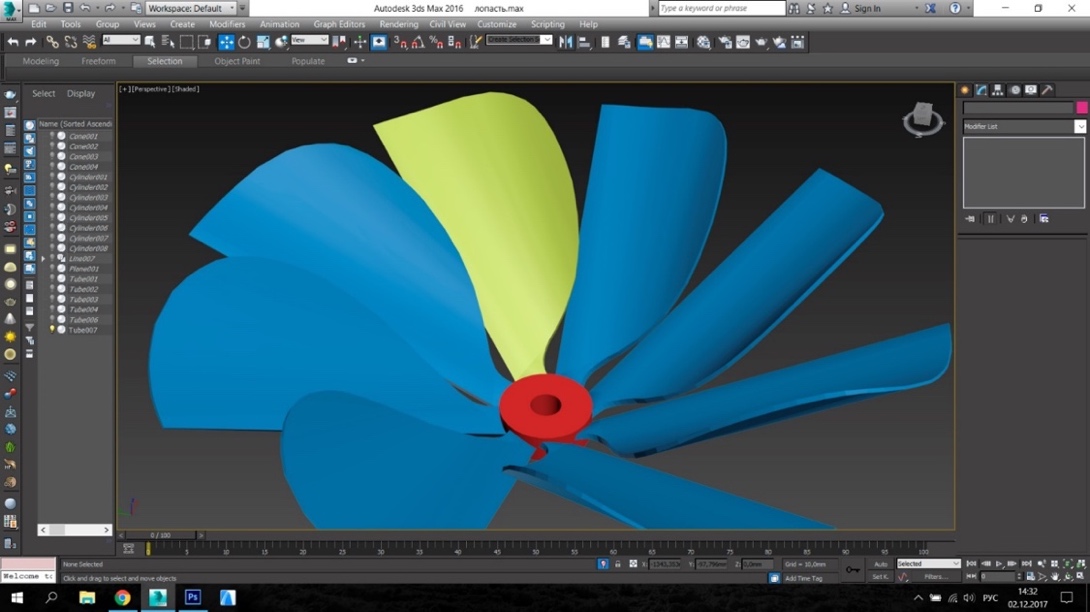

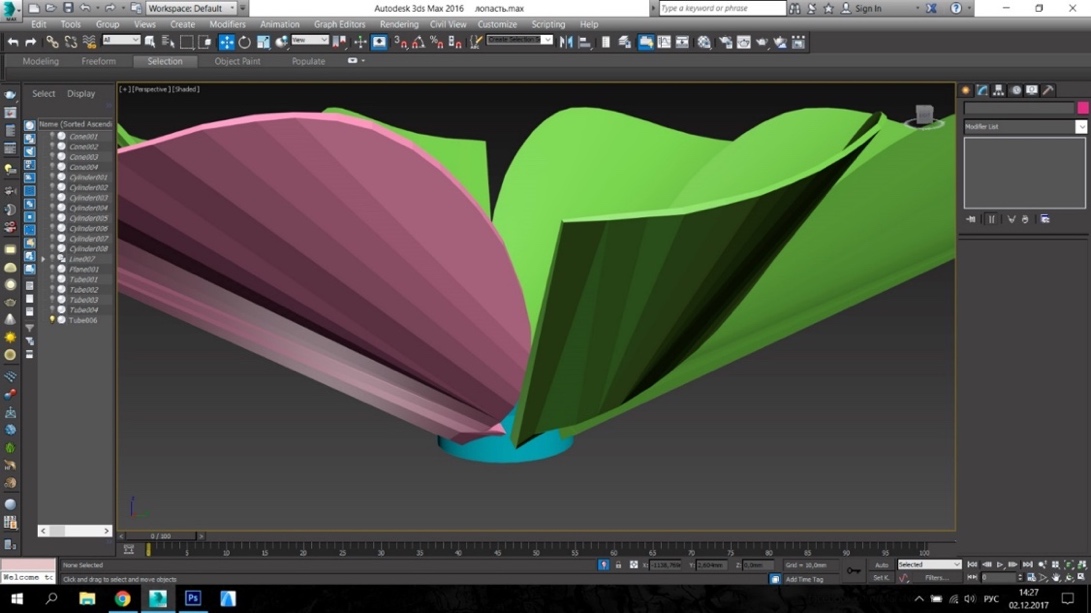

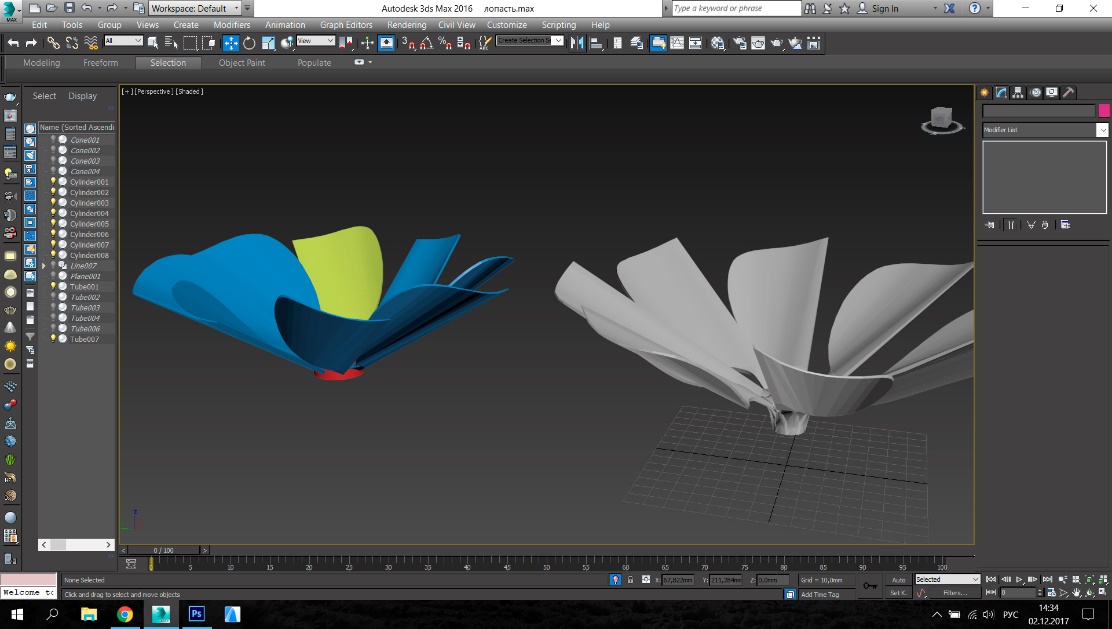

In terms of construction the new screw has not three blades with thickenings and narrowings for streamlining like a classic screw, but is made in form of a cone of eight blades. The base of each blade is a half of the Relo Triangle which is bent in a specific way.

There are a number of variations of this screw, both in its type and application:

1. The Aerodynamic screw

Patent on the Aerodynamic screw

Patent on the Aerodynamic screw

Patent on the air screw blade

Patent on the air screw blade

Refers to airborne vehicles, in particular, air and aerodynamic screws, transforming the energy of the engine into force of traction, used in aircrafts, airships, aerosleighs, hydrogliders, etc. devices.

The technical result of the proposed aerodynamic screw is achieved by the fact that the root is made unified for all blades, the internal and external surfaces of the blades are parallel to each other, the blades form a cone on their inner surface and are made with a feather, defined along the line of the curve of equal width.

Applications:

- For aircrafts, propellers of "light" aviation, etc.

- For surface and underwater vessels, in aircraft and vessel simulations.

- For vacuum cleaners, air conditioners, pumps, drying fans, etc.

- For flying toys (with propeller).

Aerodynamic screw

Depending on the application of the proposed aerodynamic screw, in wind power engineering or in propulsion devices it happens as follows:

- In propulsion devices the air flow (1) coming on the outer surface (2) of the blade creates on the blade (1) a lifting force, providing takeoff or flight. The air flow coming on the outer surface passes to the inner surface (2) of the blades (1) and moves along the blades (1) at laminar flow of air flows without their imbalance;

- In wind turbines the air flow (1) coming on the inner surface (2) of the blade gives energy and rotates the blades and with them the aerodynamic screw (wind wheel).

Advantages:

- the air screw allows to increase aerodynamic characteristics at the expense of creation on the body of the blade airfoil of laminar streams, absence of imbalance of streams from the blade airfoil, oppositely directed air flows, perceived by elements of a blade airfoil, direction of flows from one screw blade to another screw blade,

- increased efficiency of aerodynamic screw due to fuller use of air flow energy, capture of air flows of different directions, distribution of forces

- on propeller blades in presence of the air cone, the use of wind streams with different energy,

- advanced technological capabilities as a result of simplifying the design of the screw, increasing the possibilities of use in various directions, for example, in wind power engineering and propulsion devices, creating screws of different purposes, the presence in the screw of combination of blades of different shapes,

- improved performance of aerodynamic screws in form of vibration reduction on the blade airfoils by application of parent sheet, the possibility of transferring air flows from one airfoil to another airfoil of different shape, reducing noise at operation with the presence of the input and output sections of the blade airfoils, at absence of imbalance of flow from one airfoil to another,

- the blades of the wind generator feel wind speed of one meter per second that is two to three times less than the traditional blades,

- absence of noise at operation of the wind generator.

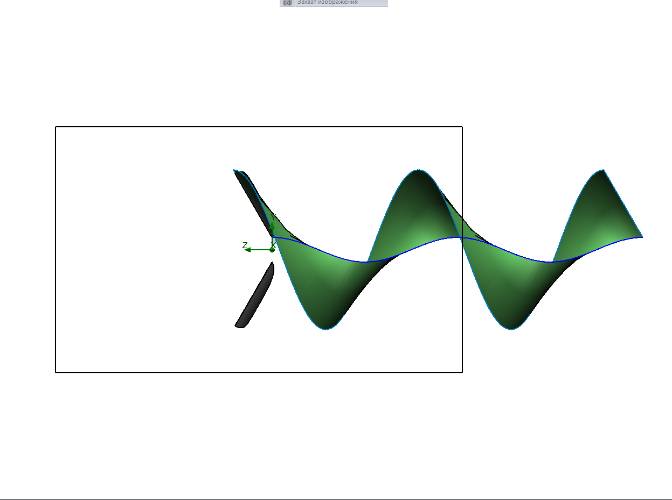

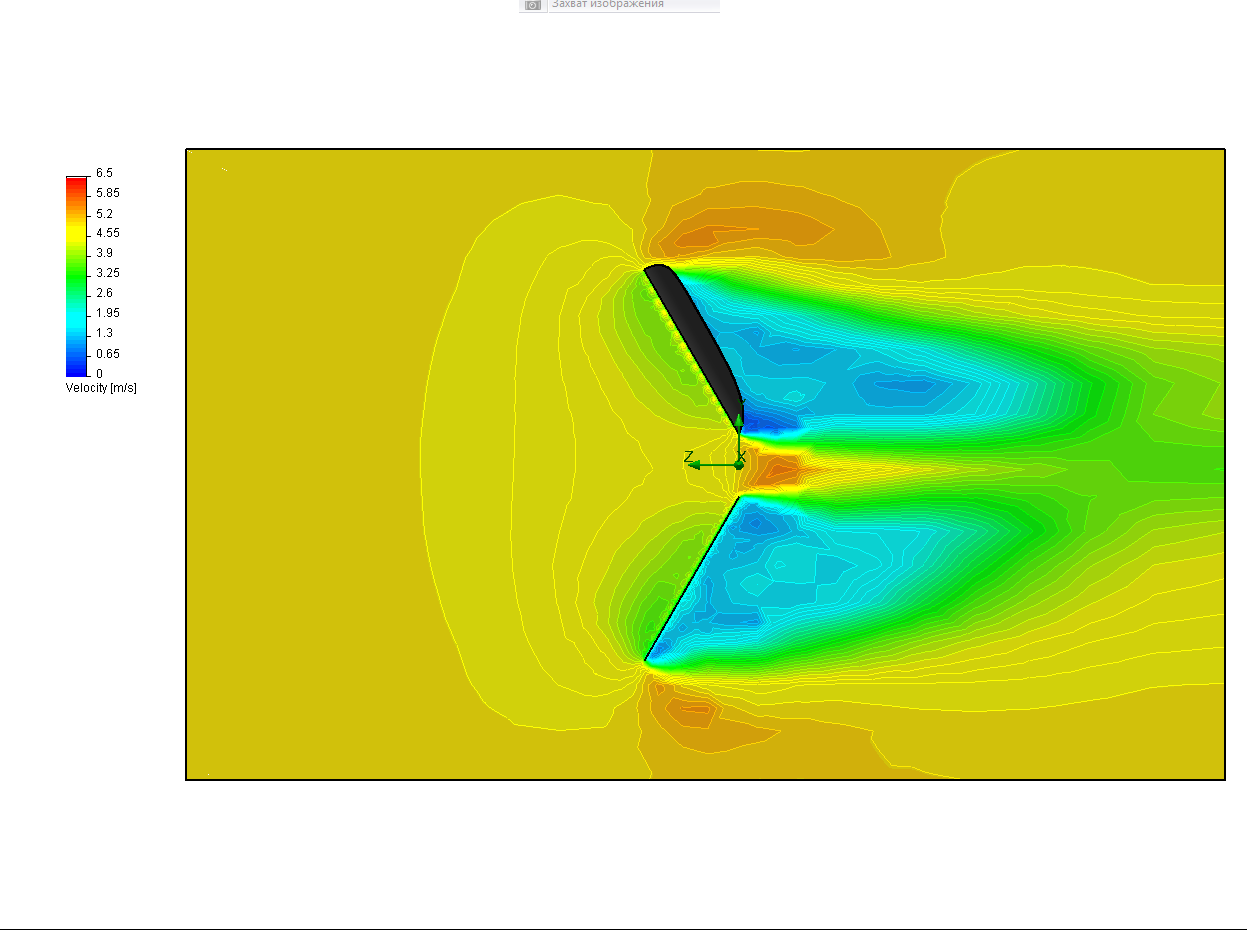

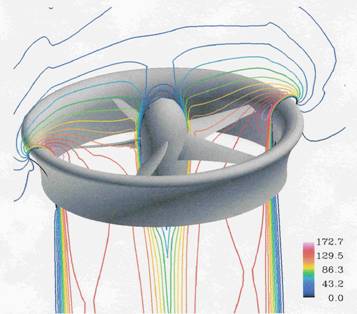

- Mathematical model for calculation and analysis of aero-mechanical characteristics of a two-bladed system of proposed screws. Testing of software complexes on control tasks. Selection of the software for the implementation of the mathematical model (see figure).

Air flow velocity field

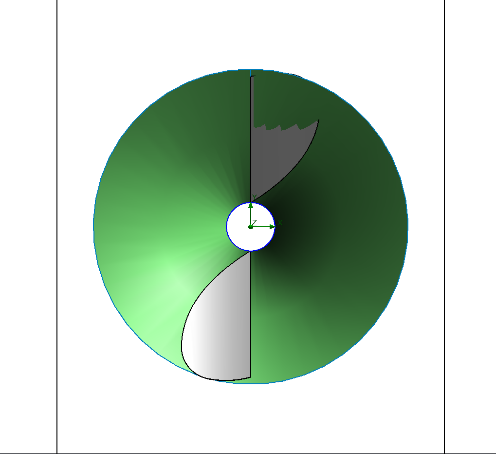

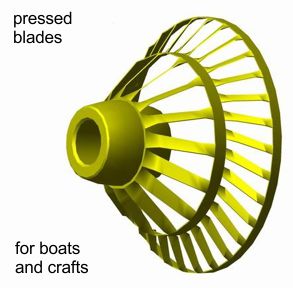

2. Screw with cumulative effect

Screw-propeller with cumulative effect (analogue patent No. 2405713)

The proposed design, significantly surpasses the efficiency factor of existing screw-propellers and is several times cheaper in production, half smaller in size, with the same thrust, and 2-3 times lighter than analogues. The design of the screw in form of a closed cone out of concave blades allows to produce the screw from thin, in comparison to its size, composite without profiling of their section on width and length. The inclination of the blades in direction of the base of the screw cone produces a soft, compared to the screws in the nozzles, compression of centrifugal flows to the axis of the screw forming a relatively homogeneous and highly-directive flow of increased density and appropriately the exit speed. The number of blades and their attack angle, angular, linear and radius dimensions of the screw and its elements are determined by the output power and speed on the shaft.

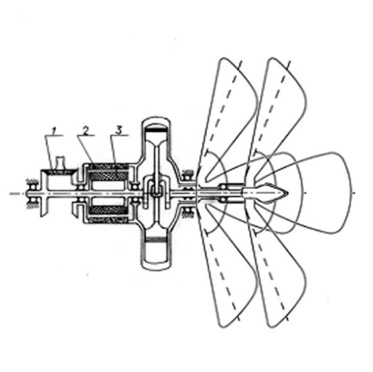

3. Counter rotation - Birotor

- The speed of the air flow in the proposed birotor propulsion device is 50% more than in conventional construction engines. With exception for the first stage, the attack angles in the new propulsion device are always smaller than in traditional constructions, thus completely eliminating the danger of stalled states, creating ideal conditions for a steady flow of gas-dynamic blast and increasing the reliability of the engine operation repeatedly.

- Only on engine and crankshaft counter rotation the aircraft will save additional about 45% of the fuel.

AREAS OF APPLICATION

1. Light aviation. Manned and unmanned aerial vehicles.

An aircraft whose takeoff weight does not exceed 5750 kg is considered to be light. For this class of aircraft, the piston engine and the air screw remain the main types of the propulsion complex.

Autogyro

Autogyro (Other name - autogiro) - a flying device which is retained in air by means of the bearing surface of the rotor - the carrying screw. It is driven not by the motor, but by the air flow. At the same time the autogyro usually has also a propeller like a conventional aircraft of piston aviation times. This marching screw gives the autogyro the horizontal speed.

2. Flying platform.

The flying platform is designed for further development and management of a new high-altitude technology based on vertical takeoff and landing to serve high-rise objects under difficult conditions. This technology can contribute to the emergence of a new class of air transportation equipment used for the transport of goods (containers), close maneuvering around the high structures, i.e. in any area of human life. Both manned and unmanned variants are possible.

The characteristics of the flying platform can be set differently and depend on the scope of its application.

Thus, to reach the load capacity up to 30 tons, the platform will have the following characteristics:

Maximum weight (gross) - 2000 kg.

Four propellers with a diameter of 1.5 m each.

Four cylinder aeroengine.

The maximum duration of work is approximately 5 hours without refuelling.

The maximum flying speed of - 75 km/h.

Maximum height - 1200 m.

3. Individual means of spatial movement.

4. V-drone (an unmanned aircraft).

A new type of drone with a vertical takeoff. Does not have any external moving parts (besides small plates for deflection of air flows) and therefore without any fear can fly near tree limbs or wires of electric power lines. To reduce weight a significant part of the construction is made of composite.

The screw in the center of the machine is used to create air flow. As in the whole series of devices of type "screw in a ring" this stream creates a reactive lifting force. And screw blades also operate on the principle of helicopter propeller.

5. Wind energy.

The sphere of application of the new screw is closely related to the alternative energy, the next step in the application of the new screw were researches in the field of alternative energy created by wind.

As result with the use of the new screw a wind propulsion system was created, the use of which allows three to four times increase the efficiency of the collection of wind power, and this in different forms. And the combination of it in modular design allows to build wind dams with any given capacity. Thus a construction of the wind turbine was created that depending on the given tasks can be of different type: from a pocket version to wind dams.

The construction of the wind turbine is based on a number of "know-how" which allows to patent the development in leading countries of the world. The preliminary patent search was already carried out, which confirms the patentability of the product.

Copyright Fulmina Foundation

Powered by Froala Editor