Project Electricity Generation

Written by Fulmina Institut

Abstract

There is an urgent need: to supply a progressive and practical solution for the millions of human beings located in many countries that do not have easy access to electricity. It is possible nowadays, to generate, locally and for all practical purpose, electrical energy at a very modest cost. Nikola Tesla, the precursor in that domain, was saying that “electricity is everywhere” and he added “we can collect it anywhere”. This caused him some opposition from the business enterprises of his time who had the goal of building all over the world the Grids that would distribute electricity, and they did not have the intention of distributing it for free. It is necessary that in these developing countries, energy be available at a price that will not gouge the budgets of these countries and families. There exist some technological applications that demonstrated that we could generate impressive amounts of electrical energy at a very reasonable and accessible cost. These technological applications allow us to approach all forms of electrical generation and distribution, for industries, but also for individual consumption, and for communities of different sizes. It is necessary for our social stability that individuals in every society have access to this essential form of energy to satisfy their fundamental daily needs in sanitation and food preservation.

This position paper was produced by « Fulmina Human Resources Foundation ». Some of the scientific and medical terms were extracted from Fondation Wikipédia to whom we are thankful "

World stakes of making electrical energy available

It seems at the least quite surprising that more than one hundred years after the discovery of electricity, we are still facing the challenge of providing this vital resource to millions of people in so many different countries, and that the monopolies of distribution are still counting on huge network of wires and pylons that are harmful to the environment, especially when they cross over urban areas causing problems particularly to young children.

If the inventor of electricity, Nikola Tesla, affirmed from the start that “electricity is everywhere” and that “we can collect it anywhere”, why then, have we built all these monstrous electrical infrastructures?

The generation of electricity MUST be local, autonomous, aneutronic and affordable for all.

The first principle of the generation of electrical power MUST be that it should be LOCAL, ideally attached to every single household, autonomous in its production, i.e., depending as little as possible on its existence from the presence of another source of energy; it should not require from its users to spend a big part of his/her budget and save it for those absolutely necessary items like education, health and feeding. The existence of another source of energy as a support for priming the system or maintaining its flow, when there is no other alternative, must be easily accessible, not be the cause of an added carbon footprint due to its transportation costs, therefore should not need to be replaced more than once a month if at all possible. Ideally, once the system has been started, it should continue to maintain its flow of energy with the help of a stocking device capable of restarting the system or maintain its operation.

The second principle is that the utilization of the system does not involve any health hazards for individuals nor the environment, that it should not be the cause of secondary pollution, as it is the case for the fossil fuel, coal, and petroleum to generate vapor for a turbine. Certain Nordic countries understood that it was wiser to utilize their underground thermal sources to generate the steam necessary for their turbines. As far as the health of individuals, one must avoid the electromagnetic fields of more than 750 KEV. These major vibrations have serious consequences on the intra cellular and extra cellular osmosis and can provoke a long-term mitochondrial alteration of the cells.

Note :

750 KEV : This is only true for alternative currents. If DC current were used, there would not be problem with the electromagnetic fields. We have today available technologies that would allow us to transform into DC, which was not possible at the time of Tesla.

The mitochondrion has an intrinsic energy in its mitochondrial DNA Function between 5 and 20 microamps See Lapis Elixir

The third principle is that any system of electricity generation should be either entirely autonomous or at least almost entirely autonomous; it should not strictly depend on the necessity of the existence of certain atmospheric conditions, like it is the case in the solar production units. There are parts of the planet where darkness of the night is present for long periods. Other situations where light is obscured by clouds and darkness becomes a threat. Every system that takes advantage of certain predominant atmospheric conditions, must equally foresee situations where an emergency systems triggers in, that could face a situation of becoming permanent.

The fourth principle is that this system must be generous enough to procure the citizens enough energy to satisfy their minimum daily needs at the minimum price as close to zero as possible. We believe that a quantity of 50 KW/month/house as a first step, and the units could be expanded or replaced over time, while recycling the existing units.

The fifth principle is that this energy must be provided by systems that will not produce any radioactivity, against which we have to protect every form of life. Three-Miles Island, Chernobyl, Fukushima, just to cite a few of the most frightening cases. All if not most of the nuclear stations producing electricity, are suffering from a radioactive leaking syndrome. They leak radioactive wastes in the environment. Unfortunately these informations are not always published. These very expensive systems all end up causing catastrophes. Then, billions of dollars and countless human lives have to be spent to clean up these consequences. All of these financial and humans resources could have been used for much more productive usage.

The last principle is that we must foresee ways of maintaining our social fabric when eventual natural or manmade catastrophic situations will hit us without warnings. These solutions must carry different characteristics:

Capacity for a house or a community to generate its own electrical energy

Capacity to generate on the spot all energy needed by the community

Capacity to generate all drinkable water necessary for the need of the community

Knowledge of the necessary extraction methods for the essential ingredients of life, like oxygen necessary for an agriculture technology

Knowledge of the necessary extraction methods for the nutritive and curative elements of plants and minerals

Knowledge of the building of ships to navigate waters

Means of local locomotion

Categories of technologies of electricity generation

1. Technologies entirely autonomous or partially autonomous:

Fenestration Technology: Windows capable of generating energy by transforming the passage of photons into electrons, either to create heat in winter or cool in summer. This existing technology is the example of a partially autonomous technology dependent on the presence of light.

The tribo electric reactor is capable of producing 52 million electron-volts from ¼ watt of electricity at 120 hertz. This dependence can be replaced by different systems capable of supplying the same energy via autonomous sources, batteries, solar technologies equipped with storage units when light is not available. This reactor can be designed and built for generation of electrons in line with the needs of daily life. Housing unit, building complex, industry, village or city.

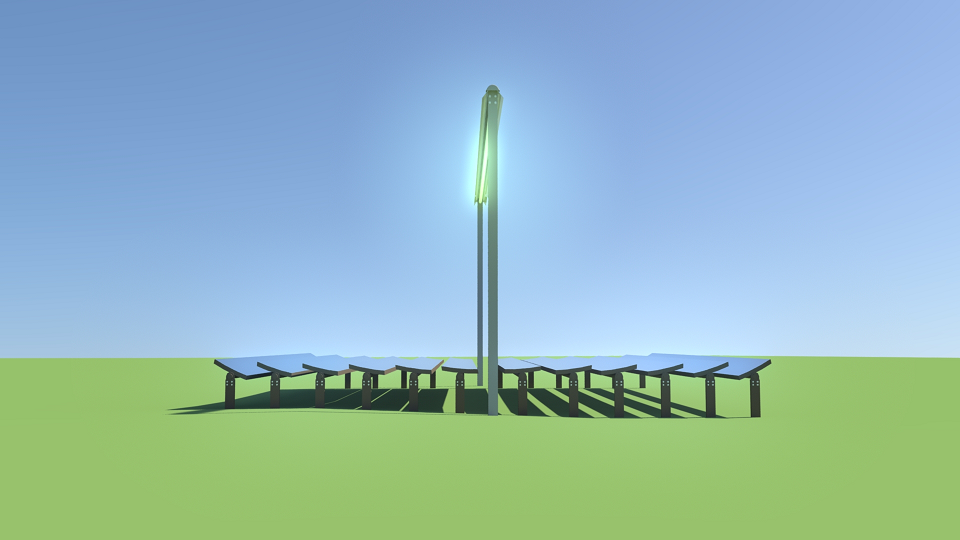

The Fresnel Solar concentrator type EH2 Solar, is one of the concentration technologies that concentrates electric energy during the day and can stock it for nighttime utilization, because the degree of efficiency of the system makes this feature possible. This technology uses panels made out from recycled plastic, like the one that pollutes the oceans (The 7th Continent). A container can generate for one village, quantities of electricity of up to 15 Gigahertz. We consider this technology as partially autonomous that necessitates a very small infrastructure of distribution.

There exists panoply of various technologies to which we have access. We are presently evaluating essentially to determine if the raw materials needed for a mass production would be available and whether this would represent a durable solution.

2. The partially autonomous technologies require a very large infrastructure level. They are expensive and have a tendency to create some toxic effects on the environment:

Hydro-electric dams

Radioactive Nuclear Stations

Wind Mills

Photovoltaic Large surfaces

Coal and/or Fuel producing Central

3. Small emergency and large scale Industrial Generators

Household generators that will provide a few hours on a tank of fuel

Large industrial generators that can provide energy for a whole building

Problem at hand and avenues for possible solutions

Our goal is not to replace the existing network of electrical distribution and their heavy infrastructures. They all come with their load of consequences and have been favored in most of the industrialized nations of our planet. Certain countries already were made aware that they have to draw emergency measures in order to face possible tragic consequences that could happen following the decisions they have made in their choice of infrastructures. It is the case for the super hydroelectric dams. However, this is not our purpose. We mainly want to address the crucial problem that until today, millions of individuals in many continents still do not dispose of an affordable access to this essential resource to maintain a simple life characterized by needs like health care, healthy food, education and in communication means, as it is the case in most countries of the planet.

There are a variety of technologies that are available. Their costs vary considerably and the necessary infrastructures needed for their use makes most of them a difficult proposition as a sustainable solution, as much as for reason of their hidden and future costs, as it is for their immediate availability.

We chose to concentrate our analysis on the electric generations that are non-polluting, those that are either totally or almost totally autonomous in their applications. Namely, they do not require additional infrastructures like access to petroleum, coal or diesel. We know for example that the cost of the transport of electricity in most cases represents more than 66 % of the total cost of the generation of electricity. We equally know that there are ways of avoiding those costs and find simpler and more direct technologies.

Each situation must find a maximum solution. Be it for a single household, a small village, a large village, a town of over 100,000 people or a megapolis. This evaluation work of those best approaches in regard of each particular needs, is a work in progress. To the best of our knowledge we are not aware that any exhaustive research has been conducted in order to answer the ensemble of questions on the viability and efficiency of different technologies for the generation of electricity in each particular situation described above.

We are going to present certain solutions that are all of them pointing in the direction of efficiency and durability. Namely we are going to evaluate the consequences for this planet of the decisions of mass production of a product in relation to another product, its efficiency factor and of the final cost to the consumer.

We are not presently in position (The Fulmina Academy who listed this question to its agenda), to provide this complete analysis, but we are in position to point in the direction of what seems at first sight, more practical, less polluting, less expensive while being accessible to the greatest number of people.

Tribo Electricity

Nikola Tesla, the inventor of electricity, gave the name Tribo Electricity (from the ancient Greek, Tribo meaning friction) to all form of energy that is produced when there is friction. Every human being discovers very early in life, the phenomenon of the lightning. When clouds are passing over each other there is some contact that generates friction that causes a massive zone of ionization in a region of the atmosphere properly called the ionosphere. This friction in certain conditions will generate with the inverse polarity of the earth, an electric discharge of many billions electron volts. It is important to understand this complex mechanism in order to learn how to collect this form of energy. How does that happen?

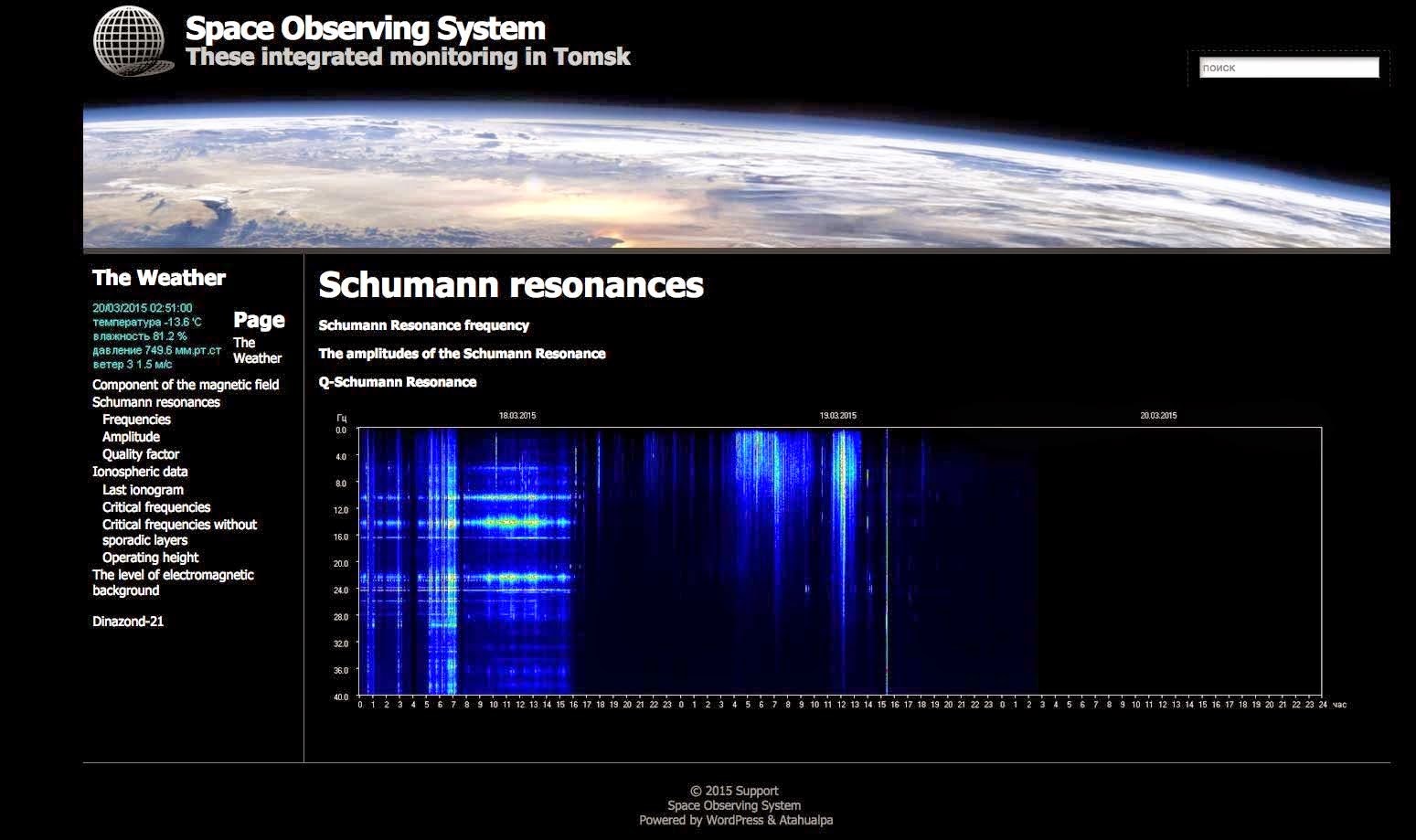

The discovery of the « Zero of Schumann »

To understand this extraordinary powerful phenomenon, we had to wait for the discovery that is attributed to the German physicist Winfried Otto Schumann who discovers in the 1950s what is now referred to as the Schumann Resonances, a network of low frequencies waves. We needed to wait for a decade before they were measured. Georges Francis Fitzgerald (in 1893) and Nikola Tesla (in 1900), already had suggested the idea that the frontier cavity between the surface of the earth and the ionosphere may serve a conduit to propagate the waves that are in relation with the telluric network of the earth crust (Hartmann Network): there exists three lattices: the terrestrial lattice discovered by Dr. Ernst Hartmann de Mannheim, but we also have a lattice located at the limit of the stratosphere and another one that is located at the limit of the ionosphere.

Note :

These three lattices were known empirically by different civilizations that built the different temples or monuments throughout the world. We are speaking of the Isle de Pâques, the Mayas, of the temples of Africa, the Celtic dolmens, but also of Egypt, of India, of China, etc. By way of information, the pyramid of Ghizeh was built over a very particular telluric site called Gigal or Nashareth (the underground network). Its height is proportional to the circumference of its base. The Egyptians understood that they could utilize different lattices since they installed at the top of the pyramid on the orichalcum triangle, a crystal in the form of an Eye that allowed them to collect certain energies to influence the climatic equilibrium of Egypt.

We refer the reader to an Internet link to view an animation that offers a clean representation of what these resonances and their energetic consequences resemble, on the planet and on the populations.

Schuman Resonance Animation : Click Here

Schumann resonances are an ensemble of low frequencies oscillations from 3 to 30 Hz – even more – of the terrestrial electromagnetic field. These resonances emanate from the internal cavity formed by the earth’s crust, the later being in mirror reaction with the ionosphere, namely, the superior portion of the atmosphere of our planet. The electrical conductivity characterized by the partial ionization of the gases of the ionosphere, provokes the electromagnetic fields to go through the earth’s lattices.

The phenomenon of lightning materializes following a natural call of primary excitation coming from the earth. Therefore, there is a call – and this phenomenon has been captured by an amateur photographer in the form of a small lightning coming out of the earth. This call provokes immediately an electric discharge accompanied by a lightning that rejoins the one coming from the earth.

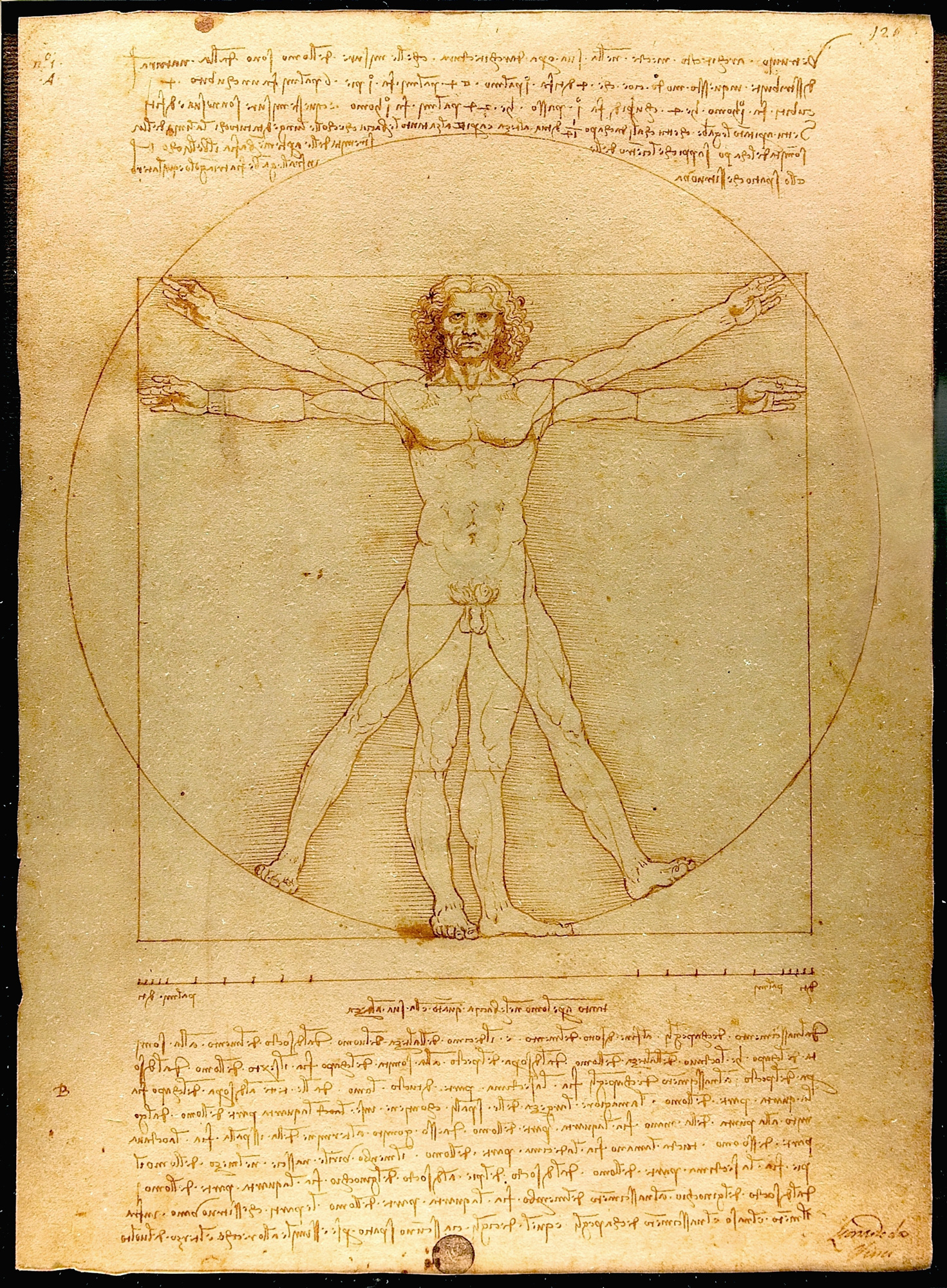

It is therefore not surprising to witness that the resonance system that triggers massive quantities of energy in the geophysical system of the planets, would have it’s equivalent in the biological system and the physical proportions of the human body (See Fibonacci and the Golden Number). The human body is in mathematical and geometrical proportion and relation with the planet earth, but also with our galaxy and the rest of the universe. Specific frequencies exist that are in relation to the sevenfold man and its different levels of conscience that trigger the chelate minerals that carry the information directly effecting the reading of the codification that liberates the different energies acting at the level of each specific endocrine glands.

Note :

Sevenfold man: Human has nine levels of resonance, but only seven of them can be part of his direct conscience. The eighth level of resonance is a passage key to the ninth level representing in the sacred texts of our humanity, its body of light and immortality.

These seven different levels of conscience have been photographed by a technique known as electrophysionic (among others).

The chelate minerals are found in infinitesimal traces – there are ten of them – and they correspond exactly to the different planets of our solar system. Lead (Saturn), tin (Jupiter), iron (Mars), cupper (Venus), mercury (Mercury), silver (Moon), gold (Sun), three other planets namely Neptune, Uranus and Pluto define Space, Time and the Direction of our DNA structure in regard to the Point Zero of the Universe. Their three corresponding metals depend essentially of the vibratory conscience level of each individual. (This thesis was presented to the French Academy of Sciences in 1973, but was recognized and confirmed by the Fathers of the Academy, only four years later).

We refer the reader on the studies of the human body by Vitruvius (between -80 et -70 ad.), roman architect, civil and military engineer who live before Jesus-Christ, as well as to the exceptional work on the sacred geometry of the human body by Leonardo da Vinci (the compass, the ruler and the square).

We observed that specific frequencies would trigger or block transfers of information for the lecture and or interpretation of the eight levels: these frequencies (vibratory support/vibratory energy) then liberate the different codifying energies.

The studies undertaken by our medical team demonstrated a technique of diagnosis, as well physical as vibration based. This practice allows making a very fast diagnosis on the illness itself as well as on the cause of the illness. It enables to immediately find the proper medicine and the origin of the pathology, be it physical, emotional or mental, and he can explain it to the patient, that can be physical, emotional or mental.

We succeed to provoke a correction of the pathology by means of an analysis of the vibratory support: the comparison between the vibratory support and the vibratory energy. This technique allows a direct interpretation of the energy, of the codification of the chapters of our DNA. This energy allows the opening and/or the closing of both the reading and the interpretation of those sequences (of our DNA). The later are in relation with those energy frequencies (vibratory support/vibratory energy). These frequencies are expressed from 7,5 to 7.8 pulsations every picosecond 10-9 (1 picosecond = 1 billionth of a second). These pulsations are in “fractal” correlation (fractal: a folded up world) with the pulsations of the earth (the earth’s pulse or the heart’s pulse of the earth) and the energies emitted by our solar system. The total frequency (at the first frequential level) gives the number 72 (9 times 8) corresponding to the eight sequential of the DNA. This subject is vast and complex; it would require an explanation of these relations with the epigenetic and the Ghost DNA, this one composed of not 2 but 12 helixes.

The maximum of the Schumann Resonances vibrates at the harmonic of 528 Hertz, exactly the same frequency utilized by the genetic biochemists and the biophysicists working on the phantom DNA, to repair the genetic basis of life.

Earth has a frequency since thousands of years (last reversal of the poles) of 7.4 cycles per second; it is raising its frequency since august 1983 and 1984. This raising hertzian frequency, corresponds to the changing frequencies broadcasting of the Egyptian Sphinx, himself in relation with other historical planetary monuments located at specific telluric intersections in space that are related with the constellation of Orion, of the Pleiades, of Sirius and the Constellation of the Quadrant.

The earth that we could date back approximately 1 billion years old in its actual density is probably much older. It followed some transformation cycles by vibratory and chemical resonances that were the cause of modification of its geographical and geophysical structure. The complexity of its constitution and of its cosmo telluric resonance is having an effect on the mineral, the vegetal and the “living” organic. The earth is part of our solar system, part of our galaxy and our universe and we now know that it is also part of the multiverse. We will soon learn, in a very near future about the characteristics of the existing seven (7) other universes. The earth is in movement and in permanent respiration like the particles of our cells, it is in resonance with the infinitively small and infinitely great.

Like our cells when attacked by antibodies, change their resonance frequencies while defending themselves, it is the same for the earth who, today, is crossing over a photon belt. Photons from the Greek root meaning “light”, they transmit themselves in packets of elementary energy of electromagnetic rays. These have an effect at the time of the absorption or reflexion of light by the matter.

The earth, while crossing the Photon Belt, sees its rotation speed slowing down. Which involves an augmentation of its resistance and therefore its resonance that can trigger the Zero of Schumann, as indicated to us by Gregg Braden who himself based his results of the Norwegians and Russian scientists.

The earth’s surface is an enormous magnetic lattice. There exists a “neutral zone” between the surface of the earth and the ionosphere, this space between the two of them being of approximately 55 kilometers.

The reduction of the earth’s magnetic charge and the acceleration of its pulsations, cause a reduction of its electromagnetic force. In fact, we know that during the magnetic inversion of the poles, the intensity (amplitude) of the earth’s magnetic field is considerably reduced, falling 8 to 10 times under its normal level. (Today the magnetic poles displaced themselves of 25 degrees, and the beat of the earth’s pulse, was last measured at 16,5 Hertz).

Planets follow a cycle and are in a perpetual movement in the universe. Astrology and astronomy both disciplines known since millennium, are informing us on the position of the planets and their cycles. Certain civilizations (Chinese, Egyptian, Maya and Indo-Aryan) have drawn precise charts of the planets and their future trajectories, as well as their interpretations.

They had knowledge of that the axis of rotation of the earth would not stay the same, since it is changing every 26,000 years (solar precession), date at which we estimate has already passed towards a new progressive transformation that marked the beginning of our civilization

A first polar reversal having already taken place, we can imagine that another reversal of the poles could be expected, as a natural cycle of future and needed evolution.

When the frequency of resonance of the earth, actually increasing, will reach a point of change, we will arrive at the Point Zero of Schumann. The later will bring us a terrestrial vibratory change, but also a biological one, carrying with it a modification of the conscience with political, economic and social repercussions.

Our biological resonance (vibratory support/vibratory energy) will accelerate and transform itself as we approach the Point Zero.

You now can understand why the codification of the sequences of our DNA that is ruled by the frequencies of 7,4 to 7,8 pulses every picosecond, 10-9 (1 picosecond = 1 billionth of a second), is in a fractal relation with the earth’s pulsation. This Point Zero will bring us most probably towards a new interpretation of the sequences of our DNA carrying with it a change in the collective conscience.

We are conscious of having outpaced our subject, but it became obvious to us that it was important to present this subject in its vital context, the issues related to the actual availability and transportability of electrical energy being of the essence. Electricity, like oxygen, is a direct manifestation of life. We must understand it and the full nature of its context.

The Tribo Electric Reactor: intellectual property protection

Description | Country concerned | Patent No. | Date of publication |

Device and Method for Molecular Polarization in Water | USA | US6,451,208 B1 | 17 Sept. 2002 |

Idem | Canada | CA2,324,374 | 14 Octo. 2008 |

Idem | Europe | EP99911544.7 | National Phase |

Idem | Brazil | PI9909415-0 | |

Idem | China | ZL9980586.8 | 25 August 2004 |

Idem | India | IN/PCT/2000,0049/MUN | |

Idem | Japan | 2000-5411002 | 25 May 2007 |

Idem | Mexico | PA/a/2000/009554 |

Second Mster Patent

Description | Country concerned | Patent No. | Date of publication |

Treatment of Fluids | USA | 6,913,382 B1 | 5 July 2005 |

Idem | Canada | CA 2,406,379 | 18 Sept. 2007 |

Idem | Europe | EP01923887.2-2104 | 27 Oct. 2002 |

We have physically demonstrated – in front of the committee for the registration of the Master Patent – our capacity to generate an electromagnetic corona of many tens of millions of electrons volts from a source of energy of ¼ of a watt. We recreate inside of the reactor the same conditions that trigger the electric discharge of the lightning, know as tribo electricity.

Tribo electricity can be produced at a very low price for all countries. It allows to be used in multiple applications: to manufacture oxygenated water (See Index on Agriculture), the desalination of seawater, and the treatment of wastewaters of municipalities. All of that because of its capacity to generate massive quantities of electricity at low cost.

It is the “least expensive” form of electricity that we know of. It is now our duty to design different forms of this tribo electric reactor so they can be adapted for the production of different energy requirements.

The new Linear Fresnel solar concentration technology

Specifications

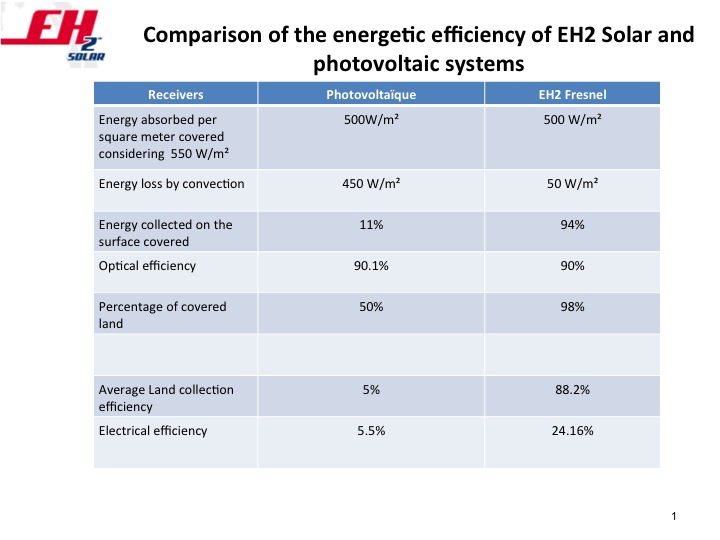

For an equal surface coverage of panels, a photovoltaic power plant can generate during hours of maximum sunlight, either 1 MW of electricity at midday, while EH2 Solar technology generates 1 MW of electricity plus 1.5 MW of heat 24 hours a day, for about $ 0.03 per KWh of electricity. Taking into account the factor of effectiveness of this technology, this represents 4 to 5 times more electrical energy per day than photovoltaic’s.

It requires less space on the ground than other solar technologies.

When a solar plant is also connected to an existing network of electricity, the passing of a cloud won't destabilize the distribution network.

Solar installations are calibrated to produce enough electricity to generate hydrogen that will be used to generate electricity during cloudy periods, using engines described below. Excess hydrogen will also be used for transport and supply electricity to smaller surrounding communities. We also have technologies to purify biogas produced from biomass liquid and dry. The methane hydrogen mixture can then provide a high-performance, low-cost and very clean fuel.

Comparison from the photovoltaic solar market

Since our concentrated solar plants allow reaching more than 40% of electrical performance compared to a conventional rate lower than 10% for photovoltaic’s, furthermore considering that the energy which is not converted to electricity (60% of the energy captured) - can directly serve heaters or even serve for air conditioning through an adsorption air conditioning system. Thermal energy that is captured during the days is therefore stored in reservoirs to meet the energy demands throughout the day. With a photovoltaic system the cost to store 1 KWh is approximately 10 times higher than the cost of production of this same KWh. The cost of storage is already included in our calculation and we can therefore generate 24 hours a day unlike the photovoltaic and other solar technologies.

Since we produce 1 MW 24 hours on 24, 365 days per year and that this equipment has a duration of life of more than 100 years, with a cost of operation and management of $ 200,000 per year per MW. The initial cost per KWh will be 1.8 M$ / 24 hours / 365 days / 100 years / 1000 KW / MW is $ 0.02 per KWh. To this should be added the maintenance costs of $100 000 / 24 hours / 365 days / 1000 KW / MW = $ 0.228 USD / KWh. Therefore the total price is less of 0.03 per KWh. If we capitalize these equipment over 5 years instead of 100 years the basic investment represents 0.04 USD per KWh what is already more than half the current price of energy in remote regions. The greatest advantage of this technology is that we produce energy close to where it is consumed.

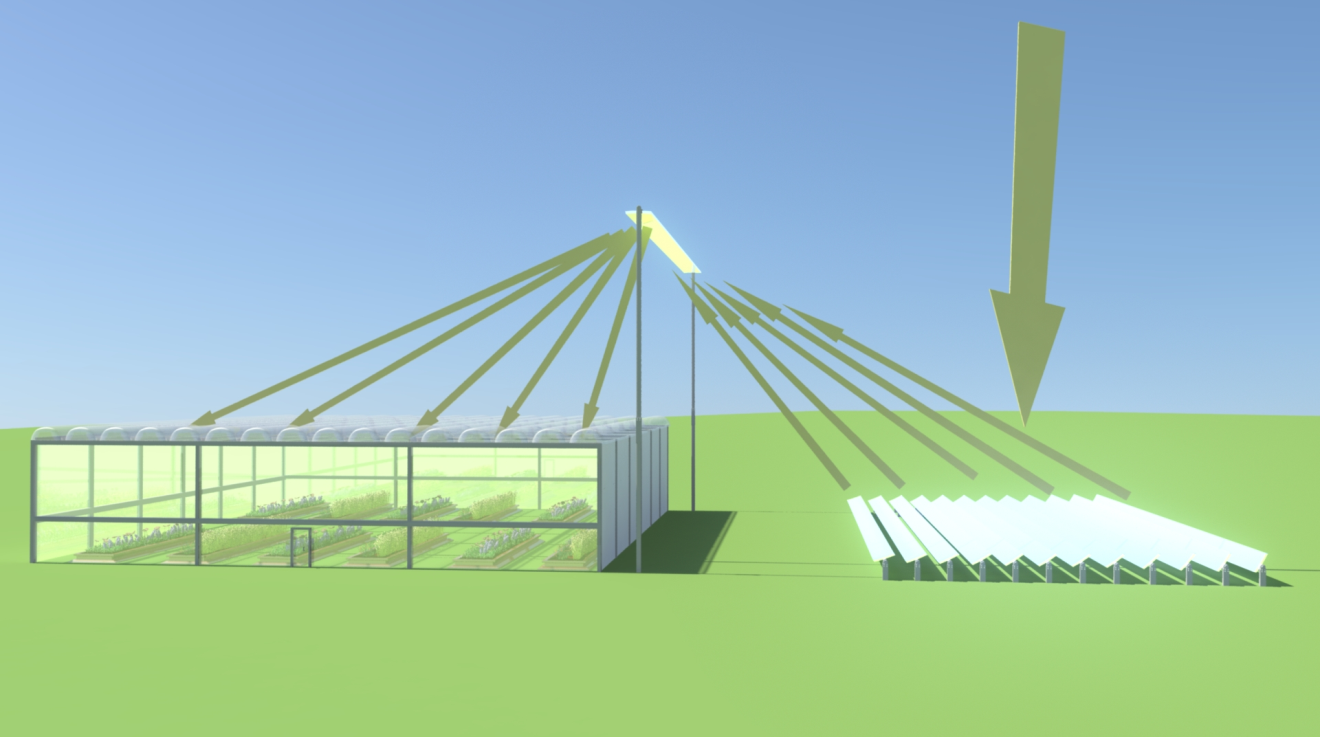

EH2 Solar technology for greenhouses (light, electricity, heat)

EH2 Solar technology for greenhouses (light, electricity, heat)

This ideal solar system provides direct additional solar energy and will provide heat and electricity inside greenhouses during the optimal time for any type of plant.

Allows an independent agricultural production throughout the year, especially where greenhouse technology uses the misting super oxygenated water (see Agriculture).

Liquid technology of new engines to natural gas and hydrogen

This technology enables to reach 83% electrical efficiency when using liquid natural gas since it takes advantage of the cold generated by the regasification. The École Polytechnique de Montréal participated in this study.

Natural gas is already two times cheaper than the different kinds of diesel fuels.

In the case of air transportation, in fact, 50% of the load that can be carried by an aircraft is used to transport fuel. Increasing the efficiency of the engines will enable to carry more passengers and payload.

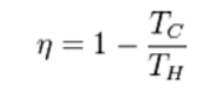

Hydrogen carries much more cold and has a lower temperature reference. In addition it carries 2.4 times more energy per kg than the jet fuel currently used. It is for this reason that we can reach a mechanical efficiency of over 95%. This is four times higher than the current Jet and gas turbine aircraft engines. Unlike current engines of this type, whose high temperature turbine components are constantly subject to contact with very high temperature gas, the components of our engine - such as the pistons - are in contact with the hot gases, for less than a hundredth of the total cycle of the piston. This is why it is possible to increase the temperature of combustion at more than 2500/Kelvin. The possible theoretical maximum efficiency is dictated by the law of Carnot, this same efficiency of diatherm engine (at two temperatures - a hot side and a cold side) works according to the Carnot cycle with a temperature hot spring TH and a cold source of temperature Tc which gives the following equation:

Second law of thermodynamics : Click Here

Therefore = 1-20 / K/2500 / K = 99.2% of theoretical maximum efficiency with our engine which is adapted to take advantage of two resources provided by hydrogen.

The basis of our engine was developed by R. Morgado. We have adapted it to the characteristics of natural gas and hydrogen for more performance and better performance.

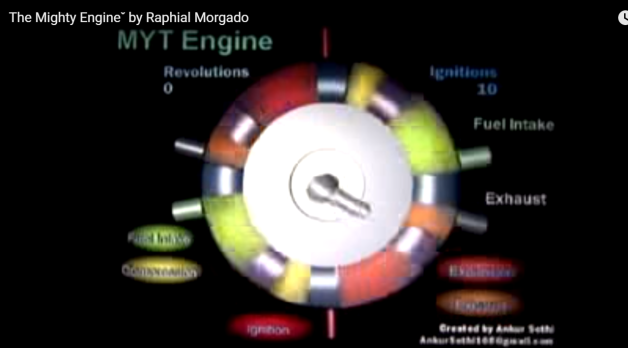

Characteristics of the engine

This engine is also a positive displacement pump. It lacks valves; these being the main cause of the problems of auto combustion in the cylinder. They keep a higher temperature than the temperature of auto combustion. The engine can be used as compressor or expander. Hydrogen having a higher temperature of auto combustion and a more rapid flame propagation speed, allows us to achieve remarkable performance. To watch Click Here

32 explosions for each round for an 8-piston engine.

The Russians have produced an already marketed version.

Its weight/power ratio is optimal and inexpensive because it has fewer components. Thanks to the version that we have developed for aircraft and boats, we need 10 times less weight of fuel for the same distance. It is also possible to mix hydrogen and methane to obtain a median boiling temperature. Aircraft specially adapted for this market to remote villages can achieve the transport.

Annexe I

Annexe II

Description of the Solar Concentrator Technology:

Important note: to facilitate the comprehension we included a glossary of the definition of certain technological terms:

Polypropylene («PP»): hard polymer, rigid and resistant to abrasion. Integrating some fiberglass particles augments its basic physical properties. It is untearable, flexible, light and recyclable;

Expanded Polystyrene («EPS»): polymer obtained by the mixture of gas and basic polystyrene namely the PS crystal. It is hard, breakable, transparent and rigid;

Polyurethane: urethane polymer – polyurethane foam possess some isolation qualities for sound and thermal. They stick to any support and can float.

PCT: Patent Cooperation Treaty – Patent international treaty allowing the registration of a patent in many countries at the same time.

PEEK: PolyEtherEtherKetone thermoplastic polymer, semi-crystalline, thermos table of high performance. It is remarkable as far as his extreme resistance to high temperatures, to chemicals, to durability, its mechanical properties and its form keeping stability. It is used principally to reinforce structures in carbon fiber or as coating on non-lubricated mechanical pieces in both medical and aeronautical areas.

PEI: PolyEtherImide is a high performance polymer that maintains its force and rigidity at high temperatures. It is remarkable for its resistance to shearing and inflammability; (aeronautical approved compound)

FRP: Fiber Reinforced Polymer

AS Composite is a private Canadian company that specializes in production processes optimization and manufacture of innovative composite products due to its unique and patented method of continuous manufacture of sandwich panels using thermoplastic polymers. Presently, several types of ASC panels are successfully in use in different industries such as transportation and construction in North America.

ASC’s main objective is to establish a strong partnership with his partner to transfer its existing technologies and to maintain further development of these technologies that will enhance the economic and environmentally friendly production of composite sandwich panels.

ASC’s goal is fully convinced that its technology is best suited for the above-mentioned proposed construction, transport, automotive and other application in solar Technology. It permits to meet three (3) very important objectives for the country - i) give access to workers to affordable and nice homes; - ii) generate jobs for these same workers in local manufacturing facilities; - iii) use a technology that has little impact for the environment; - iv) capitalize from the construction application to provoke establishment of others related manufacturing units to supply components necessary to manufacture the homebuilding panels and to exploit eventually many other applications that use ASC technology.

We believe our product and process directly speaks to the issues implied by Sustainability;

- The ASC panel can be made from recycled materials and the finished panels and any waste generated during production can be recycled as well.

- The ASC panel is impervious to water, will not rot, will not support mold, is highly impact resistant and UV resistant and can be made fire-proof. Therefore, the structures built this way will have a much greater service life the conventional materials with little maintenance required.

- Due to high insulation value of ASC panel used in building systems, required energy for heating and cooling along with maintenance effort will be greatly reduced.

- The ASC panel system produces no off-gassing and is completely environmentally friendly.

- The continuous process with a very high production rate consume less energy compare to any other fabrication method so wont contribute to pollution

- ASC has plans to incorporate Bio and wind power attributes where appropriate.

A. Introduction and importance of the proposed Product/Technology:

ASC’s leading edge and patented technology addresses three (3) distinct manufacturing abilities each with its own market potentials. Using a controlled process of pressure and temperature, the ASC process heat bonds co-mingled fiberglass and polypropylene yarns that have previously been woven into a material. The ASC process allows for the continuous roll forming of a composite plate material, sandwich panel or shape.

Overall market size has not been determined due to the magnitude and variety of applications in markets such as: transportation, recreation, construction, residential, and industrial. New product potentials are being discovered constantly. For example, 1/3 of production, for an American based truck body manufacturer, will use 3.25 million sq.ft (.325 million sq. meters) of sandwich panel annually.

Composite Plate (sheets) can vary from 0.5 mm to 6mm in thickness resulting in variations in rigidity, fastener retention, impact resistance and durability permitting a panel to be designed for a specific application.

Sandwich panels vary from 10mm to 200mm in thickness and can utilize a variety of core material such as polypropylene honeycomb, EPS, neomex, aluminum honeycomb, and polyurethane. They can be designed for specific applications where impact resistance, lightweight, corrosion resistance, impact resistance, insulating abilities and strength are all factors. Truck bodies, bus floor, ships deck and walls, airplane floor, car parts, stages, housing, cement forms and scaffolding are a few of the applications currently using our panels. Again, the market is extremely large and is worldwide.

Roll forming and in-line forming of shapes, such as corrugated panels, specialty sandwich panel inter-layers, and highway guard rails are a few applications. One of the American states currently purchase 32 km per month of guardrail. We are currently in the process of seeking Department of Transport approvals. Our guardrail will weigh less than 50% the current galvanized steel one, will not corrode, will do less damage to vehicles upon impact and will have a longer life expectancy.

Markets are recognizing the advantages, one application at a time, of our roll-formed and composite technology. Traditional applications and manufacturing processes are being replaced for lighter weight, more impact and corrosion resistant materials. Our ability to roll-form to whatever lengths are required, to join panels together to specified widths and our performance in extremes of temperature, give ASC a definite flexibility resulting in a major advantage in the various markets.. The main advantage of our process is the strength of our heat-fused bonding ability. This permits us to offer a life-time warranty against de-lamination.

B. Products and production technology (machine):

1. Product description (ASC panel)

ASC Panel is a sandwich panel consisting of a core covered on two sides by a Glass reinforced polypropylene plate. Depending on the type of material used as core, the standard panels of ASC are divided into two families:

a.Panel with solid core or polypropylene honeycomb;

b.Panel with foam core (EPS or polyurethane)

Principal benefits

The main benefits of ASC panel are as follows:

Extremely lightweight (a 4 ' x 8 ' x 3/4' ' weighs only 36 pounds);

Panel thickness ranging between 5 and 49 mm, for panels with honeycomb core and up to 200 mm for panels with foam core, of a maximum width of 2.5 meter and an unlimited length;

Bolting with using composite (or metal) profiles inserted inside the panel during manufacturing, or use of threaded insertions;

Possibility of forming the panels in three dimensions.

Maintenance-free, life-durability: resistance to the putrefaction and the mold;

Non-toxic, entirely recyclable;

Excellent resistance against various loads such as wind or seism;

Excellent impact resistance;

Extremely resistant to fatigue, moisture, corrosion and other environmental and chemical factors;

High tolerance to temperature variations (- 40C - 100C);

Resistance to fire propagation;

Fast and automatic manufacture process;

Easy and fast panel installation;

2. Description of machine and production process

The operation of the two existing patented machines is based on the same ASC innovative process and is described as follows:

Step1- Feeding: during this step, the raw material placed on parallel supports, enters the system in the form of woven tissue made of polypropylene and glass fibers. In the case of sandwich panels, the core material is introduced into the machine at the same time as the tissue in the system;

Step2- Heating and consolidation: The tissue intended for plates are heated by electric elements located throughout the heating zone and then consolidated by compression rollers. In the case of sandwich panels with polypropylene core, the plates already manufactured are put in contact with preheated core material and are fused together under the effect of heat and the pressure.

It is clear that in the case of simple plates, the machine is fed only by one of the tissue rollers and the plate obtained is not put in contact with any core material.

Step3- Cutting: The plates and sandwich panels manufactured in step2 enter in preprogrammed cutting system where they are sawed and finally charged in the trucks. In addition to the possibility of producing plates and sandwich panels, the machine is designed to fabricate profiles and corrugated plates, which could be used for applications such as guardrails and roofing.

The ASC machine, which is currently in service in Point-Claire, allows the manufacture of solid panels or sandwich made up of the following elements:

Skins covering the panel’s core. These skins are made of composites with thermoplastic matrix reinforced by continuous glass, carbon or kevlar fibers;

A core (sandwich) made of various light materials such as: polypropylene honeycombs, polyurethane or expanded polystyrene (EPS) foam, aluminum, wood of balsa, etc;

Inserts in various materials used for reinforcing or installing the panels;

Various surface films to increase the aesthetic aspect of the panels, the fire resistance, to better fight the effects of environmental and other factors associated to specific application such as anti-slip or surfaces capable to accept painting or other materials finishing.

3. Advantages of product and manufacturing process

Continuous manufacturing process of thermoplastic sandwich panels:

Although thermoplastic composites have very interesting physical and mechanical properties, their use in large scale was always limited. This was mainly due to the high costs and difficulties related to fulfillment of different laminating cycles, which consists in the simultaneous heating in order to melt the matrix under a high temperature while consolidating under pressure and finally cooling to complete the solidification. This consolidation was traditionally carried out on presses, which limited the productivity rate and molded panel dimensions to those of its plates. This traditional process results in high manufacturing costs and a varying quality. By using the traditional method, a 4' X 8' panel is fabricated within half an hour.

The ASC continuous process was developed to follow different fabrication steps in a continuous and automated manner with a production rate of 4 to 6 feet per minute. Thus, this innovative method accelerates the manufacturing process as quick as 15 times.

In addition to the production speed, which was always problematic, the phenomenon of delamination, this consists in the detachment of the sandwich panel of its core under load, was always very alarming for the users of this type of products. The reason for this phenomenon is that in the majority of the processes, the plates are bonded to the core by adhesives, while in the case of ASC thermoplastic cores; the components are associated together by fusing them together during the manufacturing process, which eliminates to 100% the delamination phenomenon.

The ASC process has the flexibility in forming of profile or 3D parts. Drums can be changed to obtain continuous profiles or in-line molding system can be installed at the end of line to produce 3D parts.

This automatic molding process at high speed, which ensures a clean operation, consistent and uniform quality had not been developed before. Thus, this process allows manufacturing sandwich panels or 3D parts out of composite materials in an automatic, continuous and clean way.

This method uses the effects of temperature and pressure in a continuous manner. As raw material, the process uses a woven tissue, containing continuous fibers and the thermoplastic resin.

Comparison with standard materials although favorable, is not always the best criteria to use because of the versatility of our manufacturing process. We design product(s) to suit the application. Basic material comparisons, as an example, are as follows:

Steel – ASC panels are 4 times the tensile strength of steel at the equivalent weight. Our panels will not rust and will not react with “dissimilar” materials – i.e. steel and/or aluminum.

Aluminum – ASC panels are 53% the weight. Upon impact, ASC panels will not deform. They absorb impact, flex, and return to original shape. Aluminum does have a smoother surface but usually requires many rivets to install and it will tear or puncture easily.

Concrete blocks – Our ASC panels have passed the Dade County Florida Projectile test. This test is done using a 8 ft. - 2” x 4” piece of wood that is fired end-wise at the test panel. The test is passed if the projectile does not pass completely through the panel. After 5 repeated impacts at the same location, there was “no visible sign of impact” on the outside skin of our panel.

Compare to a concrete block, if impacted at the center web will resist the impact but then shatters. If it hits at the void, it passes through the block except for the last 6” of the board.

ASC panels will not rot, corrode or deteriorate over time, they have better flexibility and weather resistance and they are considerably lighter and easier to use.

Plywood - ASC Panels are lighter weight, will not rot, will not split or splinter. They are not affected by moisture, nor will expand with humidity. ASC panels are initially more expensive but life-cycle costs are far superior.

Thermoset Composite- The majority of Thermosets emit toxic gases during manufacturing and in service, they become fragile at low temperatures and they are not recyclable. Their low resistance to impact limits their use in applications where the resistance to impact is essential (Example in hurricane-prone zones where each object outside the building can act as a projectile);

C. Uses and applications:

Recreation: Boat decks, recreational cabins, snow slide bases, football pads and other sports protection products…;

Construction: Concrete forms, scaffolding planks, platforms, molds for concrete beams, bridge decks, water dikes, crossing boards (spans), ramps;

Transportation: Truck bodies, roof sections, locomotive and truck doors, flooring, ramps, roll-up doors, highway guard rails, wind deflectors, side skirts, and lightweight containers;

Marine: ship and offshore deck and accommodation walls;

Aeronautic: Floor for plan and simulators;

Residential: Housing, pre-fabricated and insulated, roof panels, balconies, interior and exterior walls, sun decks, storage sheds, retaining walls, exterior stairs, walkways, lightweight garage doors;

Automotive: Inside parts for car, bus;

Military: Lightweight ordinance containers, observation shelters, lightweight, bullet resistant panels;

Other: ASC is only limited by our imagination and ability to bring the product to market i.e.: boating industry, aeronautical industry, etc.

Annexe III

Application of tribo electricity: waste waters and desalination of seawater

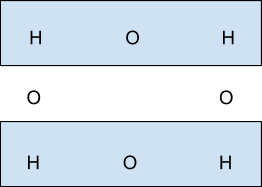

The electromagnetic corona that we create allows us to break the molecules (without production of radioactive neutrons) and to separate their atoms; it is the case in the treatment of waste municipal waters and/or the desalination of seawater.

In another application we integrate an atom of Oxygen inside of the water molecule.

Problematic of the integration of a Oxygen atom in a water molecule

Figure 1. Two water molecules H2O are facing each other. The two molecules encircled are maintained in a stable and permanent state by the strong nuclear force. If we introduce Oxygen atoms in between the Hydrogen atoms of the water molecule, that are facing each other we have to convince the four Hydrogen atoms to establish a liaison with the two Oxygen atoms. It is the role of the weak nuclear force to establish the stable liaison, but not permanent one. We are still in the presence of H2O.

Annexe IV

Copyright Fulmina Foundation

Powered by Froala Editor