The Deuterium Project

Written by Fulmina Institut

Deuterium The Infinite Source of Energy

This position paper was produced by « Fulmina Human Resources Foundation ». Some of the scientific and medical terms were extracted from Fondation Wikipédia to whom we are thankful.

History

During the 70ies, the environmental preoccupations were centered on the future of generations. We were preoccupied on predicting if we would have enough petroleum resources for future generations.

At the same period, the relations between those who owned the resource and those who distributed it, were tense. They were essentially fighting to obtain more equitable share of the profits. It followed with an increase in the price of petroleum; we rapidly witnessed a few years later, exorbitant prices. The barrel of fuel reached levels as high as $160 US. Prices at the pumps in Paris or Tokyo crossed over the barriers of $7 dollars a gallon.

Then the real environmental preoccupations started to fill the air. Fossil fuel started being pointed at as the root cause of pollution of the atmosphere. In every major city around the world, citizens were warned in subways and on major arteries with signs posting the pollution levels in the city, informing the citizens of those “acceptable” levels and those that we should avoid as being dangerous for health. The governments did not hesitate to join the dance and target the petroleum resource to impose sales taxes that in most cases had for effect to double the prices established by manufacturers and distributors.

We have an alternative solution, which has the advantage to reduce the pollution close to zero, eliminating graves risks to the public health and to the environment. This resource is available.

We owe this solution to Dr. Edward Teller, co-founder of Lawrence Livermore National Laboratory (LLNL) Click Here , situated in the State of California; he single handedly identified the solution to our future energy needs.

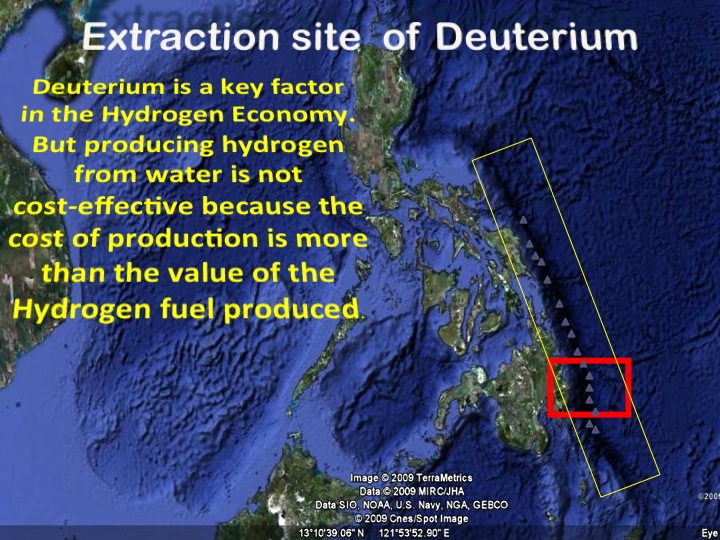

Dr. Edward Teller demonstrated the existence of other solutions than petroleum; Deuterium, which was believed to exist mainly in the vicinity of stellar constellations, was in fact in full presence on our own planet. Dr. Edward Teller had access to some observation data provided by satellites that were pinpointing to the presence of unlimited resources in the depth of the oceans, a substance known as Deuterium (2H) indicating that its atomic weight is double than the one of the Hydrogen molecule (1H). The Deuterium is located at the bottom of the oceans, and is in movement according the movement of the Earth Inclination. When the Earth’s Inclination is moving in the “direction of the Pacific ocean”, the heavier than water Deuterium present in the bottom, starts a sliding motion in the direction of the Asian continent, and finds refuge in those deep trenches. The trench becomes a captor that retains the Deuterium from escaping in the other direction, when the Earth’s inclination movement goes in the opposite direction. Every night as a consequence of this sequel, an impressive amount of Deuterium is captured in the depth of those trenches.

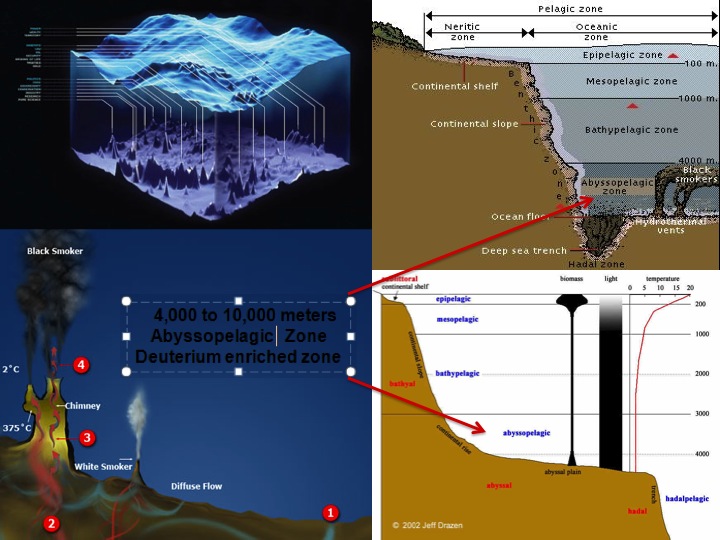

The effects of the pressure exercised in the depth of abyss

One of the deepest trench and also one of the longest reaches a distance of more than 800 km long with depth as profound as 10 km deep. At this abyssal depth, pressure is such (1,000 bars) that any structure will be submitted to radical transformations. Deuterium will not escape to this fate, and it transforms itself into Hydrogen (1H not to be confounded with H2 dihydrogen often miscalled Hydrogen). Hydrogen being lighter will escape the trench to reach the surface of the ocean and dissipate in the atmosphere.

Dr. Edward Teller conceived the idea to photograph with great precision by satellite, the exact position of this trench and had the foresight to involve the right people that would, upon his request, protect this resource for the future of Humanity.

The Actors

Professor Guy Montpetit, Scientific Director of Fulmina Foundation, worked with Dr. Bogdan Maglich, who invented an a-neutronic Reactor (a nuclear reactor that does not produce any radioactive Neutron) using fusion of Deuterium/Helium atoms, for the generation of electrical energy. At the same period, Professor Montpetit was made aware of Dr. Edward Teller’s preoccupations of providing a green solution for the consumption of our daily needs in energy. Dr. Edward Teller had indicated that the principal source of Deuterium was located well in the interior of our Planet.

Fulmina Foundation and Fulmina Limited, a corporation based in Hong Kong, registration No. 84 83 81, dedicated among other things to the protection of the planetary biotope of this Planet, established Deuterium as an environmental priority with the aim of replacing the fossil fuel in order to reduce significantly its energetic footprint. On the other side, we must underline that this Hydrogen is a gift from nature, and that its extraction will not cause any damage to the environment, will not perturb the patrimony of our natural resources; Deuterium replenishes itself every night in the of depth of marine life. Just an additional reason why our foundation is proposing to make Deuterium a priority solution. We estimate that it can last for many thousands of years without causing any dent in the patrimony of our natural resources.

The Objectives

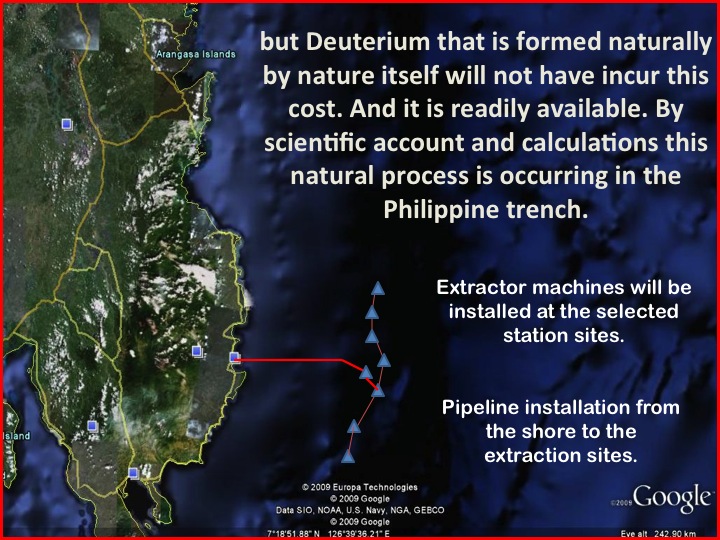

The objectives of this great project are to extract the Hydrogen produced naturally every night, in the trench of the Philippines, and to provide our Planet with a non-polluting fuel for our automobiles, planes, heavy industries like cement, iron smelters, blast furnaces, those industries being responsible for 40% of our atmospheric pollution.

There are many other applications that are susceptible to use this energy resource. All the participating countries already made a fundamental decision, at the 2015 Paris Conference on the Climate, to abandon fossil fuel if they were to reach their goal of reducing the atmospheric pollution to sustainable levels. We know that this trench is capable of providing humanity with all the fuel it needs for the next millenniums.

Pre-production

Before proceeding to the Production Phase, a Pre-Production Phase will determine a number of technical tests and parameters for the specifications and terms of reference for the Protocol of Extraction. Our fundamental respect of the marine life environment along with technical security guidelines, pumping quality, and transport of product, will direct this protocol.

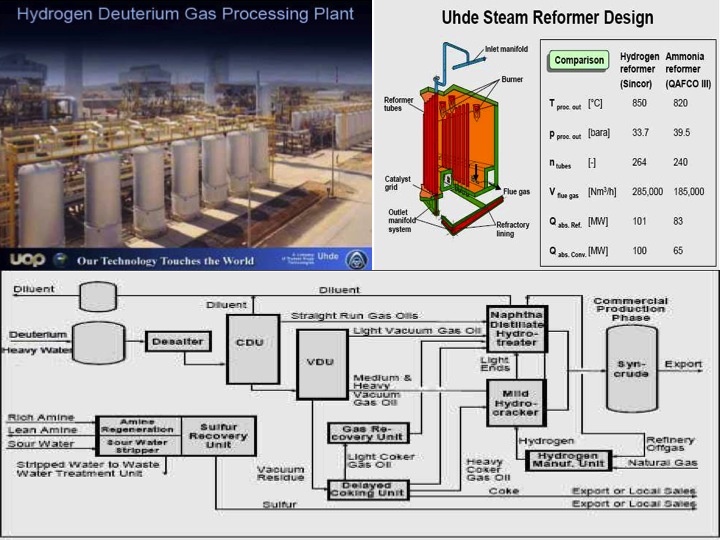

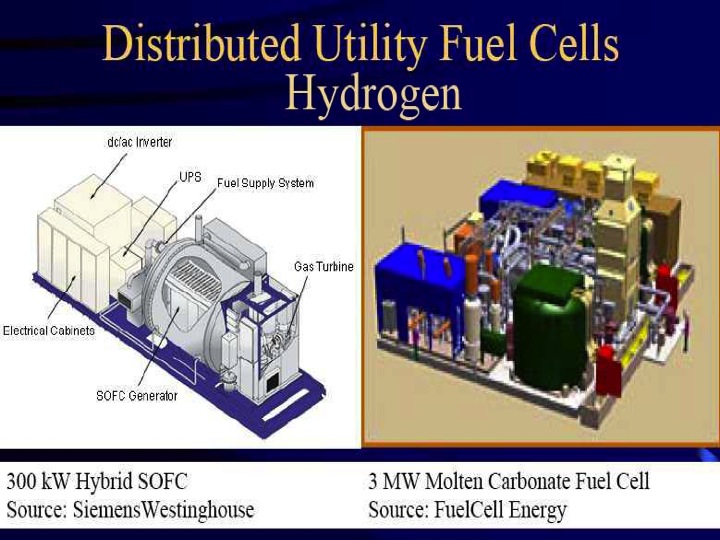

Pumping Techniques in the Production Phase

This new technology for the extraction of Hydrogen has been developed after extensive research, and new types of pumps have been designed for this project. The technology called « Ram Jet suction » allows a pumping capacity of one million barrels per day per unit. We are installing 12 units in the first phase.

Nanotechnology

We are presented with a unique opportunity to use the power of nanotubes to develop highly resistant structures, capable of supporting the 1000 bars pressure at depth of 10 km down the trench. The power of these nanotubes allows us to install pipelines at great depth without being submitted to breaks caused by these high pressures of the marine depths.

Nanotubes is an already existing technology, and one single thread of a nanotube, barely visible with the naked eye, is strong enough to support the weight of an elevator and would carry it up for distances of many kilometres.

We will expand that technology in the direction of producing longer threads that could be used in loom like machines to thread stronger and longer threads of nanotubes.

Fabrication of pipeline tubes

We will create pipeline tubes that will be used to carry the hydrogen from 10 km down the trench up to a Ground Storage facility. At depth of 10 km, pressure is such that you need very powerful structures that will not be crushed by the extreme pressures. We utilize the suspended bridge cables technique to create the texture of the tubes that we are using at these depths. The first step is to fabricate one nanotube thread, using three single threads that we are braiding together. Then, we manufacture as many of these needed to braid a bigger braided structure that will be used to create a tube made of these strong fibbers.

These tubes are capable of supporting extreme pressures in the abyss. Since we find Hydrogen between 4,000 and 10,000 meters we will produce these nanotubes in accordance to their specific response as to the level of pressure they will be used.

The Investment

A corporation will be created that will be the owner of this project. That structure will own another structure that will detain the rights of exploration of the Deuterium. The engagement of the Main corporation in return to the access of the resource for the Service of Humanity, is to return a percentage of the benefits accumulated to a number of Humanitarian Foundations, already included in the nine sectors of the Humanitarian Fulmina Foundation, with specific concentration of efforts in the domain of Education of Children and Health Care of these children.

The Budget for this project will require some ten billions dollars.

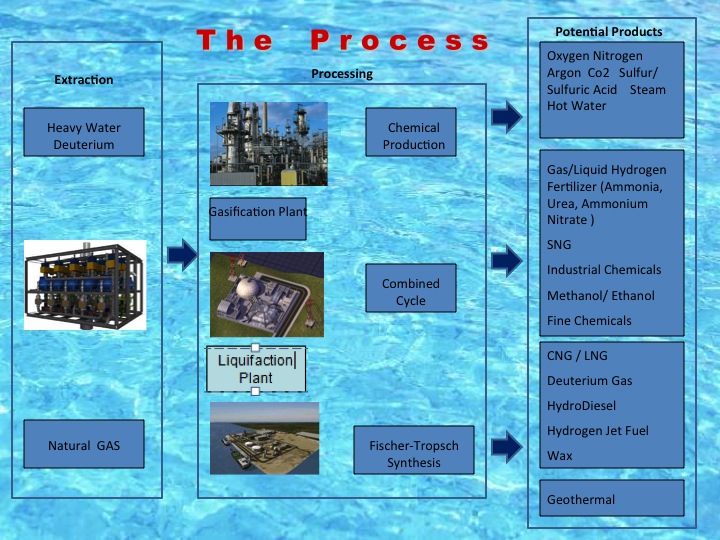

The Production Company

The Production Company will start as soon as the confirmation of the Tests Period is completed, by the positive report of the presence of deuterium and the conditions under which it can be extracted. The pre-Production period will also investigate all avenues for distribution worldwide. It is the role of the Production Company to establish partnership with dynamic petroleum organizations, to aggressively start the distribution of Hydrogen as replacement for the fossil fuel, the petroleum.

The transport of Hydrogen

We use an avant-garde technology that we explain below. Our liquefaction/degasification technology is coupled with a new solar energy that renders this application autonomous in terms of energy.

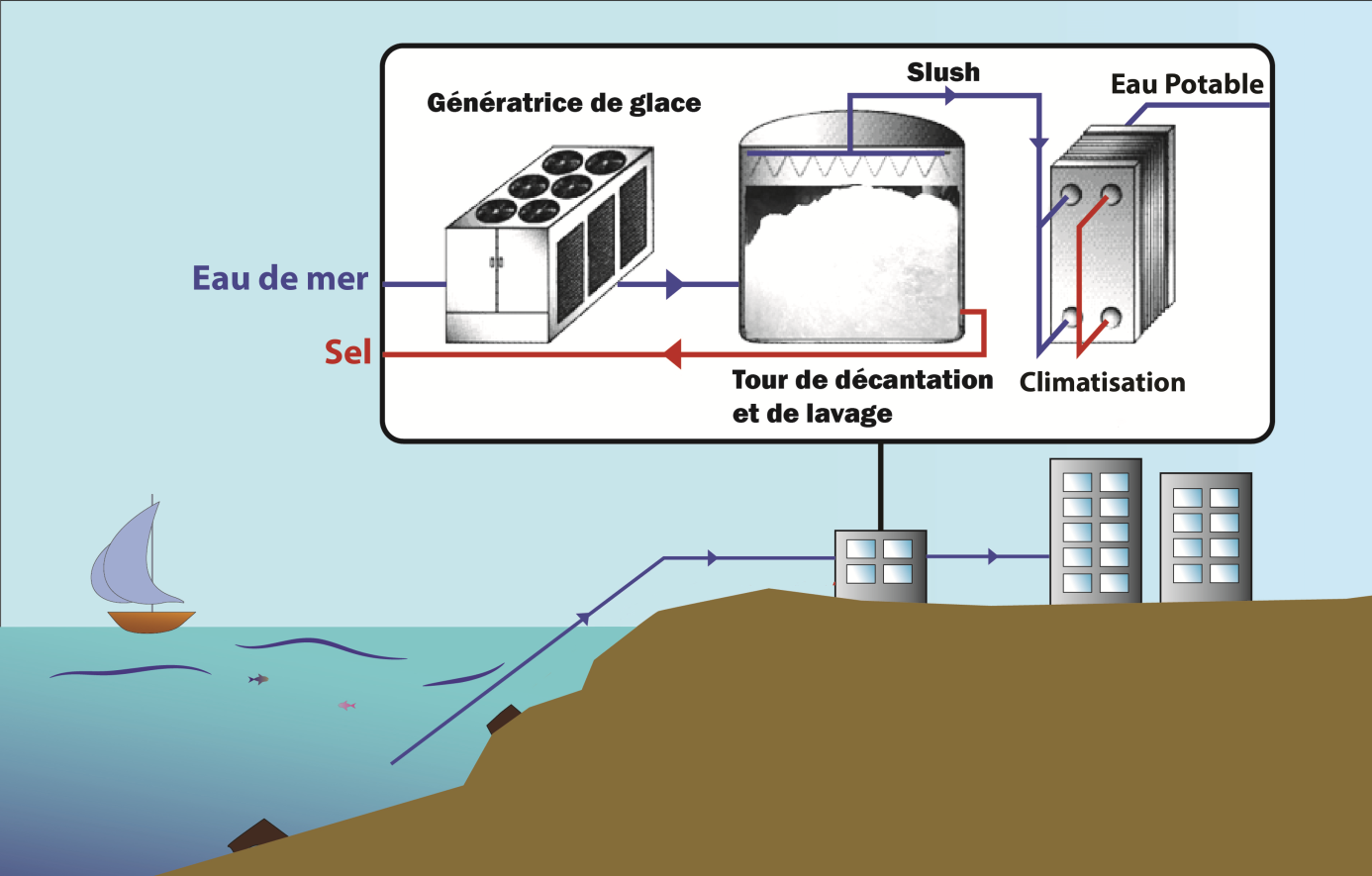

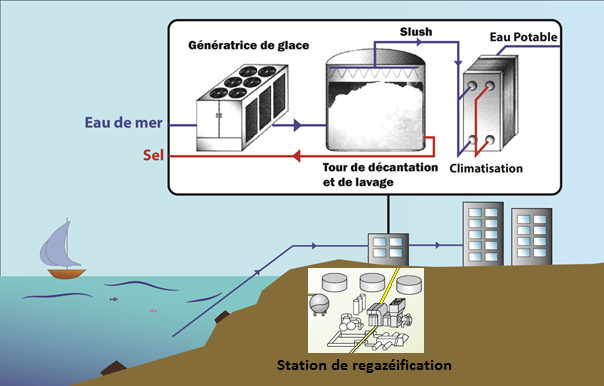

Cooling Technology for storage and transport (desalination EH2- O as premium)

EH2O is the sole technology of drinking water production that generates an energy gain with 10 to 40 times the value of water produced.

Creating an energy gain of 141Kwh per cubic meter of water produced.

Capable of recuperating salts for commercial use.

Positive impacts on the environment comparatively to the existing techniques.

Can desalinate 100% of the rejected waters of reverse osmosis systems while recuperating the salts.

Major improvement in the conservation of food (the mixture water/ice immediately cools food to 0 ⁰C in order to instantaneously stop the proliferation of bacteria).

Desalinizing water at -21⁰C and 23% of salinity (the eutectic point) the crystals smaller than 1mm that we produce, climb into the decantation tower while the salts go in a downward direction.

Transporting cold on long distances

A pipe of one meter of diameter transports 1 GW over a distance of more than 100 Km while losing less than 5% of its cooling capacity. The mixture ice/water transports seven times more cold than the cold water for the same volume. Losses during transport are essentially caused by the friction inside the pipe, since the quantity of energy transported is much more important that the losses by conduction. It is sufficient to cover the pipes with a four centimetres of isolating material to optimally reduce the losses of energy. The losses due to friction are proportional to the square of the speed of displacement of the liquid in the pipe. Since you need seven times less flow to transport the same quantity of cold, we loose 49 times less cold for a same distance in the same pipe. Moreover, it is important to compare this loss as a function of the cooling potential that is seven times more elevated. A two meters pipe transports 4.4 GW over a distance of 400 Km losing only 5% of its initial cooling capacity. A three meters pipe transports 10 GW over a distance of 1000 Km losing only 5% of its initial cooling capacity.

Advantages of the EH2-O technology for the Regasification Stations

Allows the transportation of hundreds of megawatts that are presently wasted by each gas terminal, while recuperating the mineral salts and desalinate the seawater.

The recuperation of the salts has more value than the produced water.

Allows seven times less usage of sea water and diminishes the environmental impacts in a significant way, since we transport seven times more cold for the same volume of water.

Augments by a factor of seven times the capacity of regasification of these stations for the same volume of seawater used.

Reduces the cost of new gas terminals while making them more economically sound. The cost of the pumping station and permits are a major part of the installation costs of a gas terminal.

Markets

China and India are the biggest liquefied natural gas markets in the world.

More than 1,000 MW of cooling are wasted in China alone.

In India, 70% of the food is spoiled for a lack of access to refrigeration and freezing.

The total value of spoiled food is much higher than the cost of energy.

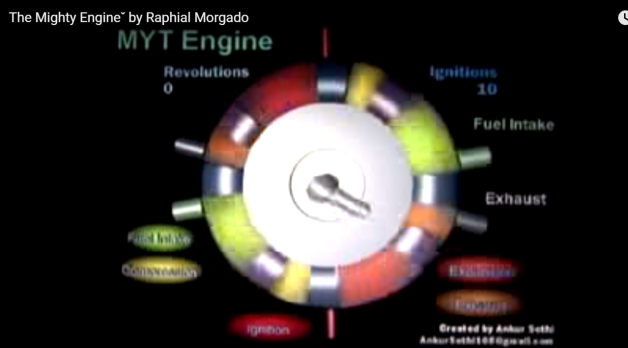

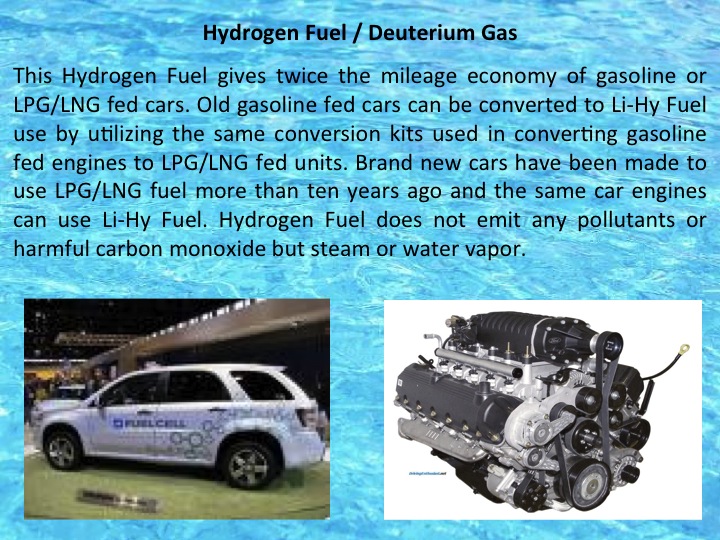

New motor Technology using liquid natural gas or Hydrogen

This technology allows to reach 83% of electric efficiency when it uses liquid natural gas, since it is taking advantage of the cold generated by regasification. This is part of a study we have completed with L’École Polytechnique of Montréal.

Natural gas is half the price of all other types of diesel fuel.

Obtaining a higher efficiency rating, will, in turn, permit the technology to become more economically sound and will diminish the environmental impacts.

In regard to the load able to be carried by a plane, one must consider the fact that 50% of that charge consists of the weight of the fuel. Augmenting the efficiency of the engines will allow to carry more passengers of freight.

The hydrogen transports much more cold and has a lower reference. And for each kg, it transport 2.4 times more energy than the jet fuel presently used.

This is the reason why we can obtain a mechanical efficiency of 95% higher, which is four times higher than the efficiency of existing jet engines and their gas turbines.

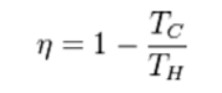

Consider also the fact that actual engines whose components in the high temperature turbine are constantly submitted to hot gases, by comparison, the components of this engine – like the pistons – are in contact with the hottest gases for only a very small portion of the time, namely less than one hundredth of the total cycle time of the piston. This is why we can augment the combustion temperature to 2500⁰K. Since the theoretical maximum efficiency of the engine is dictated by the law of Carnot, the same efficiency for this dual temperature engine (hot and cold) uses one hot source TH and one cold source TC .

Secon Law of Thermodinamics Click Here

Where = 1 –20K/2500K = 99,2% maximum theoretical efficiency with this new gas engine designed to take advantage of the properties of Hydrogen.

R. Morgado originally developed the concept of this engine. We adapted it in order to use the particularities of the natural gas and the Hydrogen molecule to obtain higher performance.

Characteristics of the engine

This engine can also be looked at as a volumetric pump. The engine doe not have any valves that are the root cause of all problems of auto-inflammation in the cylinders, by the fact that they keep a higher elevation of temperature than the threshold of auto-inflammation temperature.

The engine can also be used as a compressor or decompressor. The Hydrogen having a higher auto-implosion temperature and a faster propagation speed of the flame, are part of the particular characteristics that are responsible for these performances.

32 explosions for each round for an 8 pistons circular engine.

The Russians also produced a version already commercialized.

Its ratio power/weight is optimal and inexpensive since it has few components. The version that we developed for planes and boats requires 10 times less fuel weight to cover the same distance.

It is also possible to mix hydrogen and natural gas to obtain a median boiling temperature. Specially adapted planes designed for this market can then perform the transport. With this clean and inexpensive fuel, it is also possible to develop airplanes capable of vertical takeoff at the prices of a small intermediate car.

Liquefaction of Hydrogen

As for the production and liquefaction of Hydrogen produced from the depths of the oceans, our engineers must evaluate the probability of using the existing pressures at the bottom of those trenches, for the purpose of liquefying the Hydrogen. Certain techniques related to the transmission of harmonics in the pipes could greatly augment the efficiency of the process, combined with the use of the existing pressures. This “original idea” has the merit to be examined.

Once Hydrogen is separated from water, the existing pressure at these depths is extremely high and we should consider installing at this depth storage tanks that would then be able to use the ambient pressure (in the range of 1,000 bars) to store and liquefy the Hydrogen using that “free pressure”. This feature would also provide an additional security feature.

Using the ambient pressure along with the temperature of water at this depth to feed the cooling cycle – we can rationally estimate that it would be much less expensive (1.9 Kwh/kg) to liquefy the Hydrogen. Since at a temperature of de 100⁰ K, and a pressure of 1,000 bars, the Hydrogen finds itself almost at the same density than its natural liquid state.

Copyright Fulmina Foundation

Powered by Froala Editor